What is the CAS Modbus Scanner?

CAS Modbus Scanner is a utility to retrieve coils, inputs, holding registers, and input registers from a

Modbus-enabled device. Values retrieved from the device can be viewed in many different formats,

including Binary, HEX, Uint16, Int16,

Uint32, Int32, and Float32.

This utility can also discover Modbus devices on your network if you do not know their address. It works

by testing every address, function, length, and offset to check for exceptions or responses.

FEATURES

- Can read; coil status (0xxxx), input status(2xxxx), input registers (3xxxx), and holding registers

(4xxxx) - Data is viewable in Binary, HEX, Uint16, Int16, Uint32, Int32, and Float32

- Discover devices on your network

- Multiple connections

- Tested with 100s of 3rd party Modbus devices

- Works with RS232, RS485 and TCP

- 100% Free to use, no registration required

- Easy user interface

Downloads

Please Read the License Agreement before downloading this utility.

Modbus Scanner Quick user Guide

- Download the CAS Modbus Scanner from the executable above

- After the installation, please run the application.

- Click «Discover». Choose Modbus RTU or TCP. If TCP, enter the IP address of the Modbus TCP device

you are polling. - Locate ‘Device» These numbers are the Node ID’s that you will poll for. If you know the Node ID, you

can scale down the numbers. For example, if you know the Node ID is 1, you can use Start: 1 and End:

2 - Notice the Device and Function Code column. The Device is the Node ID. The Function Code is the

Modbus data type (see below). Use your mouse to right-click on the correct Device and Function Code

that you are trying to poll. Then click on «Add to Task List». You’ll get a pop-up letting you know

that the request was added.For example, if you want to poll 40001 on Node ID 1, right-click

Device ID 1 and Function Code 3. - FC01 — 0xxxx — Coil — Binary Output

- FC02 — 1xxxx — Discrete Input — Binary Input

- FC03 — 4xxxx — Holding Register — Analog Output

- FC04 — 3xxxx — Analog Input

- Now we can poll for those data points on the selected Node ID and Function Code!

- Finally, click «Poll». Doing this will poll for the points selected in the highlighted task. This

function will show you the offsets, standard addresses (Modbus Register), and the values.

Modbus Function Code (Data Types)

Modbus Function Code (Data Types)

Locate the IP address and Device ID (1, in this case) and right-click underneath where it says, ‘Read

Holding registers starting at 40001’. Select ‘Edit Task’. Next, choose the Offset and Length to

locate the point(s) you are looking for poll. After you’ve selected the correct offset and length,

click ‘Edit Request’

Note: Function allows you to change the function code.

Modbus

for Field Technicians (Free!)

Learning about Modbus? Want to update your Modbus knowledge? This free EBook will guide you through

basic

and advanced Modbus topics.

you can download the Modbus

for Field Technicians for free from our website.

APPLICATION and System Requirements

Use the CAS Modbus Scanner to find the correct port settings and the correct slave address. The tool

automates the process of trying all the combinations and reports the results.

The tool works for RS232 and RS485 by allowing you to search for a single device or multiple slaves. To

connect to a RS485 network from your laptop you simply need a USB-to-485 converter.

- Windows 2000, XP, Vista, Windows 7 (32bit or 64bit), Windows 8 (32bit or 64bit), or Windows 10(32bit

or

64bit) - 10mb of free space

- Modbus RTU requires an RS485 port. You will need to purchase a USB to RS485 converter (ACON U-01)

Did you know that we also service Modbus Integration Solutions?

Chipkin has Modbus solutions for almost every situation. We are experts in Modbus RTU/TCP

communication

and carry a wide variety of Modbus products:

Thanks for choosing Chipkin’s protocol gateways, data

clients,

and integration services to meet your building and industrial automation requirements!

Chipkin™ is a building and industrial automation protocol expert. We develop, configure, install and

support gateways (protocol converters), data loggers and remote monitor and controlling

applications.

Founded in October 2000, Chipkin provides

expert solutions for converting BACnet®, Modbus®, and LonWorks®—to name just a few—and enabling

interfaces for HVAC, fire, siren, intercom, lighting, transportation and fuel systems. The

high-quality

products we offer (including those from

other vendors) interface with Simplex™, Notifier™, McQuay™, GE™ and many others—so you can rest

assured

that we will select the most appropriate solution for your application.

With Chipkin you are buying a solution. Our configuration expertise in this field combined with free

BACnet and other tools ensure your success; and our customer support via phone, e-mail, and remote

desktop tools means that we’re there when you

need us. Chipkin is a small responsive company, and we live or die by the quality of our service—and

with offices in two-time zones—we can provide support when you need it. Give us a call now!

Customer Support

Chipkin is proud to provide support for the products we sell. For technical support, sales, and

customer

service, please contact us at 1 (866) 383-1657

If you work with Modbus protocols and have an instrument or device that you can connect to your PC’s COM port, chances are you may need to collect the serial data you receive for further analysis. Serial Port Monitor (aka Modbus Scanner) by Electronic Team is a universal professional utility that can easily help you accommodate almost any serial instrument with an RS232 port. This dedicated software is an optimal way to interpret or parse the messages received from or sent by your equipment.

When a device sends a message it usually contains all sorts of extra characters and codes.

Note: Serial Port Monitor works as a ModbusScanner and extracts the relevant data from each message. The app is designed to decode Modbus ASCII and Modbus RTU data received and sent through the system’s COM ports.

The program allows displaying the incoming and outgoing serial messages in the most convenient and readable format. In addition, the software comes with an advanced built-in search option and unique stream filtering tools with presets.

Here’s what our customer says:

“I used this software and found it to be incredibly user-friendly. It met all my expectations. As an electronics engineer, I used the software to analyze and communicate with my domestic devices, such as my VMC. I am planning to create a display and control module using this application. Additionally, I used it at work on industrial equipment. As a maintenance technician for radioactivity detection and monitoring equipment in nuclear power plants developed by the MIRION company, we use a Serial Port Monitor to scan Modbus RTU data.”

— AMBROSINI Frédéric

How to scan Modbus data:

Here’s how you can start a monitoring session and sniff data using the simple Modbus RTU and ASCII scanner software (Serial Port Monitor is the best option):

Choose the color for date time, header, structure, details, checksum, and errors. Then, select whether to scan Modbus data as Modbus RTU or Modbus ASCII.

Key features of Serial Port Monitor

Serial Port Monitor works as a Modbus ASCII and RTU Scanner and has proved to be an efficient tool for tracking down possible problems during the development of serial applications and drivers, testing and optimizing serial devices, etc.

Serial Port Monitor offers a host of advanced features, including:

✅ The ability to start reading a COM port that is already in use by another program. All data received by the sniffer interface is shown in real time so that a programmer can identify any possible issues.

✅ The ability to monitor multiple RS232, RS422, and RS485 ports simultaneously. If you need to analyze the activity of several Modbus ports within one session, you can easily do this with the Modbus message parser app. Data flowing in and out of the port is conveniently recorded in a single log using the first-in-first-out method.

✅ Support for several data viewing modes: table, terminal, line, dump, and Modbus visualizers. You can use all or several of them at a time. More than that, various filters offered by this utility will also serve for precise monitoring.

✅ Emulation of the data transfer to a serial device to see the exact reaction of the device to specific commands.

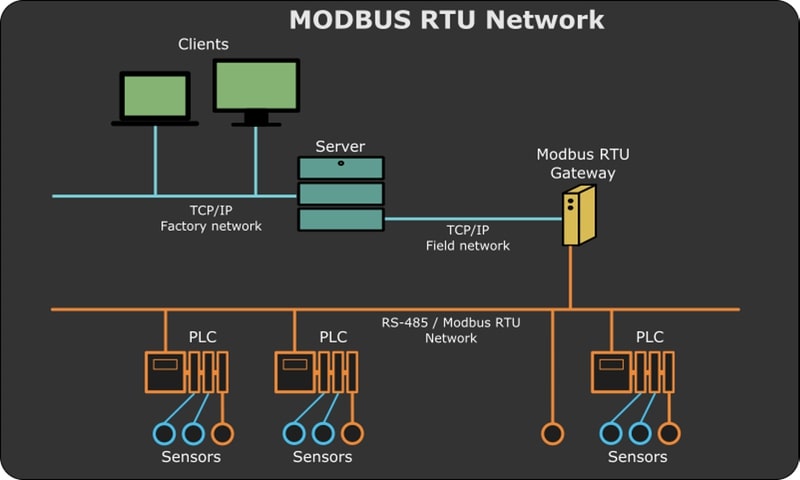

How to provide communications within industrial networks

As a result of constant modernization of production, today more and more industrial automation systems are based on distribution networks working over flexible data transfer protocols.

There’s a wide variety of interfaces and data transfer protocols that provide communications within industrial networks. These include Modbus, Ethernet, CAN, HART, PROFIBUS, etc. They allow data transfer between sensors, controllers, and actuators; calibration of sensors; power supply to sensors and actuators; communication between the lower and upper levels of the process control systems, and more.

The data transfer protocols are usually developed according to the requirements of a particular production and technical systems and provide a reliable connection and high accuracy of data transfer between different devices. Along with the reliability of operation in harsh conditions, ACS TP systems often require high functional capabilities, flexibility in construction, ease of integration and maintenance, and compliance with industry standards.

Modbus solution

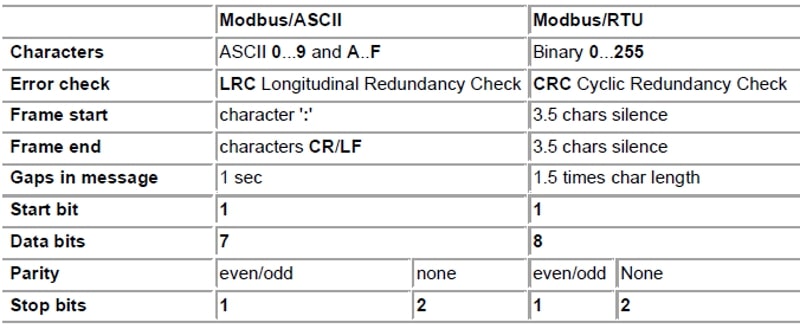

Modbus protocol is widely used as a communication channel between automation elements in industrial data networks. There are three main implementations of the Modbus protocol. Two of them are designed for serial data communication over both copper EIA/TIA-232-E (RS-232), EIA-422, EIA/TIA-485-A (RS-485), and optical (and radio) lines: Modbus RTU and Modbus ASCII. And one of them is for data transmission across Ethernet networks: Modbus TCP.

Modbus ASCII and Modbus RTU

The difference between Modbus ASCII and Modbus RTU protocols lies in the way they encode characters. In the ASCII mode, the data is encoded using an ASCII table where two bytes of data correspond to each character. In the RTU mode, the data is transmitted in the form of 8-bit binary symbols, which provides a higher data rate. With ASCII there can be a delay of up to 1 second, unlike RTU, where messages must be continuous. Also, ASCII mode has a simplified system of data decoding and management.

Modbus protocols (Modbus ASCII, Modbus RTU, and Modbus TCP) use one application protocol to ensure their compatibility. The maximum number of nodes in the Modbus network is 31. The length of communication lines and the data transfer rate depend on the physical implementation of the interface. All elements of the Modbus network interact using a client-server model based on transactions consisting of a request and a response.

Where Modbus is used

Areas of Modbus industrial application: communication of sensors and actuators with the controller, communication of controllers and control computers, communication with sensors, controllers, and corporate networks, connections in SCADA systems, etc.

The simplicity of implementing Modbus protocols has led to its wide application in industrial systems and not only. Today the equipment of almost all manufacturers comes with support for Modbus protocols.

Madwolf писал(а): ↑15 мар 2023, 20:21

Ну, для этого модбас пулл бы подошёл (показать, что там ничего нет). Выяснив адреса, но не зная что там лежит, можно ещё месяцами определять, что именно там лежит )))

В модбас пулл последних версий появился сканер регистров по одному, но он только определяет, читается регистр или нет, а содержимое не отображает. На тот момент, когда мне нужен был этот функционал, он отсутствовал . Особенности Модбаса в том, что если ты задаешь диапазон чтения регистров и этот диапазон у устройства фрагментирован, выдается ошибка чтения (Illegal address).

Если знаешь, что должно лежать в регистре (например, известную температуру или давление, которые можно задавать калибратором для стабильности), сканирование позволяет определить этот регистр.

Отправлено спустя 5 минут 7 секунд:

Jackson писал(а): ↑03 мар 2023, 13:07

В таких случаях обычно справляется модбаспул. Не раз общался с производителями на тему «а чего это у меня не читается?», присылая им скриншоты из модбаспула. МодбасПул существует с 2002 года и прекрасно работает.

функционал «сканер регистров по одному» появился в модбас пуле только в 2023 году. Причем сканирование не показывает содержимое регистров.

Отправлено спустя 53 минуты 9 секунд:

Поправка. Сейчас загрузил последнюю версию Modbus Poll version 10.4.2 Build 1930. «Сканер регистров по одному» теперь отображает и содержимое регистров.

-

morrice

- Сообщения: 153

- Зарегистрирован: 05 дек 2014, 18:39

Как найти устройство по modbus

Здравствуйте, возникла проблемка одна. с ПЛК организовывал связь с цифровым табло через modbus. У табло были исходные параметры Modbus RTU 9600/8/N/1 и модбас адрес был 1. По ошибке не в те регистры записал значения и связь с табло пропала. Вроде как как то модбас адрес поменял. Короче не могу теперь свзаться с табло, перерыл все модбас адреса от 0 до 255. не находит.

Как можно выйти из этой ситуации, как можно вообще найти модбас устройство не зная его параметры ? может есть утилита какаято, которая ищет по всем параметрам и адресам ?

Написал разработчику табло, но пока молчит.

-

morrice

- Сообщения: 153

- Зарегистрирован: 05 дек 2014, 18:39

Re: Как найти устройство по modbus

Сообщение

morrice »

Нашел что то по адресу 247, но ПЛК по этому адресу ничего не находит. Да еще и странно он нашел 6 вариаций, как такое может быть ?

В другой проге тоже нашел.

- Вложения

-

-

- 2.jpg (93.06 КБ) 6827 просмотров

-

-

-

- 1.jpg (67.31 КБ) 6828 просмотров

-

-

Ryzhij

- Сообщения: 1026

- Зарегистрирован: 26 авг 2012, 19:25

- Откуда: Россия Рязань

Re: Как найти устройство по modbus

Сообщение

Ryzhij »

morrice писал(а):Да еще и странно он нашел 6 вариаций, как такое может быть ?

Так вариации-то на тему контроля чётности. Устройство отвечает, но программа, видимо, фиксирует лишь сам факт отклика не вникая в содержание ответа типа «Ась? Не разобрал последней фразы…»

__________________________

Помощь — понятие растяжимое, всяк трактует его в меру своего эгоизма…