-

Page 2: Table Of Contents

CONTENTS 1. Model number Page 1.1 Model number —————————————————————————— 5 1.2 How to read the rated label ———————————————————— 5 2. Name and functions of the sections ——————————————- 6 3. External dimensions 3.1 External dimensions ———————————————————————- 7 3.2 Tool cable (AKT4H820) external dimensions ————————————— 7 3.3 CT (Current transformer) external dimensions ———————————— 7 3.4 Terminal cover (AKT4H801) external dimensions ——————————— 8 4.

-

Page 3: Safety Precautions

• This instrument must be used under the conditions and environment described in this manual. Panasonic Industrial Devices SUNX Co., Ltd. does not accept liability for any injury, loss of life or damage occurring due to the instrument being used under conditions not otherwise stated in this manual.

-

Page 4: Installation Precautions

• Do not leave bits of wire in the instrument, because they could cause fire or malfunction. • Use the solderless terminal with an insulation sleeve in which the M3 screw fits when wiring the KT4H/B. • The terminal block of this instrument is designed to be wired from the left side.

-

Page 5: Model Number

1. Model number 1.1 Model number A K T 4 (1) (2) (3) (4) (5) (6) (7) (8) (1) Color —————————————- H: Gray, B: Black (2) Supply voltage —————————- 1: 100 to 240V AC 2: 24V AC/DC (3) Input type ———————————- 1: Multi-input (Thermocouple, RTD, DC current and DC voltage can be selected by key operation.

-

Page 6: Name And Functions Of The Sections

2. Name and functions of the sections Model KT4H or KT4B Bottom view (Fig. 2-1) Display (1) Action indicators : Lights respectively when temperature unit is selected. : Lights during Serial communication (optional) TX output. : Flashes during auto-tuning or auto-reset.

-

Page 7: External Dimensions

3. External dimensions 3.1 External dimensions (Unit: mm) Common to KT4H/B Mounting frame Terminal cover (sold separately) Rubber gasket M3 screw (Fig. 3.1-1) 3.2 Tool cable (AKT4H820) external dimensions (Unit: mm) ø2.5 Plug 3-Pole type USB Plug (Fig. 3.2-1) 3.3 CT (current transformer) external dimensions (Unit: mm)

-

Page 8: Terminal Cover (Akt4H801) External Dimensions

3.4 Terminal cover (AKT4H801) external dimensions (Unit: mm) (Fig. 3.4-1) Note when using a Terminal cover (AKT4H801) When using a Terminal cover (AKT4H801), pass terminal wires numbered 7 to 12 into the holes of the terminal cover. See (Fig. 3.4-2). Terminal cover (Fig.

-

Page 9: Mounting To The Control Panel

Tighten screws with one rotation upon the screw tips touching the panel. The torque is approximately 0.05 to 0.06 N•m. How to mount the KT4H Mount the controller vertically to the flat, rigid panel to ensure it adheres to the Dust-proof/Drip-proof specification (IP66).

-

Page 10: Wiring

5. Wiring Warning Turn the power supply to the instrument off before wiring. Working on or touching the terminal with the power switched on may result in severe injury or death due to Electric Shock. 5.1 Terminal arrangement • EVT1 : Alarm 1 output •…

-

Page 11: Settings

Default values: Input (K, -200 to 1370 ), Alarm 1 type (No alarm action), Reverse (Heating) action If the users’ specifications are the same as the default value of the KT4H/B, it is not necessary to set up the controller.

-

Page 12: Operation Flowchart

6.4 Operation flowchart This instrument has been classified into the following modes and setting items. For 3 seconds after power on, the PV display indicates the Power ON input type, and the SV display indicates input range high limit value (thermocouple, RTD input) or scaling high limit value (DC voltage, current input).

-

Page 13: Main Setting Mode

6.5 Main setting mode To enter the Main setting mode, press key in the PV/SV display mode. To set or select each setting item, use key, then register the value with key. Setting item numbers such as [1], [2], etc. are the same as those on the “6.4 Operation flowchart” (p.12). Character Name, Function, Setting range Default value…

-

Page 14: Sub Setting Mode

6.6 Sub setting mode To enter the Sub setting mode, press key while pressing key in the PV/SV display mode. To set or select each setting item, use key, then register the value with key. Setting item numbers such as [5], [6], etc. are the same as those on the “6.4 Operation flowchart” (p.12). Character Name, Function, Setting range Default value…

-

Page 15

• Sets the heater current value for Heater burnout alarm. CT1 current value is indicated on the PV display. When OUT1 is ON, the CT1 current value is updated. When OUT1 is OFF, the KT4H/B memorizes the previous value when OUT1 was ON. -

Page 16: Auxiliary Function Setting Mode

6.7 Auxiliary function setting mode To enter the Auxiliary function setting mode, press key for approximately 3 seconds while pressing key in the PV/SV display mode. To set or select each setting item, use key, then register the value with key.

-

Page 17

Character Name, Function, Setting range Default value [22] Data bit/Parity selection 7 bits/Even parity • Selects the data bit and parity. Not available if the Serial communication option is not added or if Contact input option is added. • : 8 bits/No parity : 7 bits/No parity : 8 bits/Even parity : 7 bits/Even parity… -

Page 18: Setup Mode

6.8 Setup mode To enter the Setup mode, press key while pressing key for approximately 3 seconds in the PV/SV display mode. To set or select each setting item, use key, then register the value with key. Setting item numbers such as [25], [26], etc. are the same as those on the “6.4 Operation flowchart” (p.12). Character Name, Function, Setting range Default value…

-

Page 19

Character Name, Function, Setting range Default value [29] PV filter time constant setting 0.0 seconds • Sets PV filter time constant. If the value is set too large, it affects control result due to the delay of response. • Setting range: 0.0 to 10.0 seconds [30] OUT1 high limit setting 100%… -

Page 20

Character Name, Function, Setting range Default value [38] Alarm 1 type selection No alarm action • Selects an action type for Alarm 1. (Refer to Section “11.4 Alarm action” on p.30.) • : No alarm action : High limit alarm : Low limit alarm : High/Low limits alarm : High/Low limit range alarm… -

Page 21

Character Name, Function, Setting range Default value [46] SV rise rate setting minute • Sets SV rise rate (rising value for 1 minute). Setting to 0 disables the function. • Setting range: 0 to 10000 /min. ( /min.) Thermocouple, RTD input with a decimal point: 0.0 to 1000.0 /min. -

Page 22

Character Name, Function, Setting range Default value [54] PV color selection Green • Selects PV display color. (Refer to Section “8.4 Changing PV color” on p.26.) • : Green : Red : Orange : When Alarm 1 or Alarm 2 is ON, PV color turns from green to red. : When Alarm 1 or Alarm 2 is ON, PV color turns from orange to red. -

Page 23: Operation

After the unit is mounted to the control panel and wiring is completed, operate the unit following the procedures below. (1) Turn the power supply to the KT4H ON. After the power is turned on, the PV display indicates the input type, and the SV display indicates the input range high limit value (for thermocouple, RTD input) or scaling high limit value (for DC input) for approximately 3 seconds.

-

Page 24: Auto/Manual Control Switching

By pressing key again, the unit reverts to the PV/SV display mode (automatic control). Whenever the power to the KT4H is turned on, automatic control starts. 7.4 Indicating output MV (manipulated variable) To indicate output MV (manipulated variable), press key for approx.

-

Page 25: Basic Usage

8. Basic usage 8.1 ON/OFF control In ON/OFF control action, the control output is turned ON when PV is lower than SV, and turned OFF when PV exceeds SV. Overshoot, undershoot and hunting phenomenon occur during ON/OFF action. Therefore, ON/OFF action is not suitable for control which requires accuracy.

-

Page 26: Changing Pv Color

8.4 Changing PV color (1) In the PV/SV display mode, press key for approximately 3 seconds while pressing key. The unit proceeds to the Setup mode, and the Input type selection item appears. (2) Press key several times until [54] PV color selection item appears. (3) Select the PV color with key.

-

Page 27: Auto-Reset And Arw

9. Auto-reset and ARW 9.1 Auto-reset Auto-reset is performed to correct the offset at the point at which PV indication is stabilized within the proportional band during the PD action. Since the corrected value is internally memorized, it is not necessary to perform the auto-reset again as long as the process is the same.

-

Page 28: Auto-Tuning

10. Auto-tuning In order to set each value of P, I, D and ARW automatically, the auto-tuning process should be made to fluctuate to obtain an optimal value. One of 3 types of fluctuation below is automatically selected. For DC input, the auto-tuning process will fluctuate around the SV for conditions of [1], [2] and [3] below. Notice •…

-

Page 29: Out1 Pid, Pi, Pd, P Actions

11. Action explanation 11.1 OUT1 PID, PI, PD, P actions PI action : When derivative time is set to “0” PD action : When integral time is set to “0” P action : When both integral and derivative time are set to “0” [8] Integral time and [9] Derivative time can be set in the Sub setting mode.

-

Page 30: Heater Burnout Alarm Action

11.3 Heater burnout alarm action [15] Heater burnout alarm value and [16] Heater burnout alarm 2 value can be set in the Sub setting mode. (p.15) Alarm action Setting Small Large Load current Output Indicator (EVT2) Unlit If Heater burnout alarm, Heater burnout alarm 2 and Alarm 2 are added together, they (EVT2) utilize common output terminals.

-

Page 31: Out2 (Heating/Cooling Control) Action [Reverse (Heating) Action]

11.5 OUT2 (Heating/Cooling control) action [Reverse (Heating) action] Heating P-band (Cooling P-band) Heating/Cooling control can be used Control Heating (Cooling by adding Heating/Cooling control action action action) option. SV setting Heating proportional band can be Relay contact set during [6] OUT1 proportional band output (OUT1) setting, and cooling proportional band Cycle action is performed according to deviation.

-

Page 32: Out2 (Heating/Cooling Control) Action [Reverse (Heating) Action] (When Setting Overlap Band)

11.7 OUT2 (Heating/Cooling control) action [Reverse (Heating) action] (When setting overlap band) Heating P-band Heating/Cooling control can be used Cooling P-band by adding Heating/Cooling control Overlap band option. Control action Heating (Cooling action action) Heating proportional band can be set during [6] OUT1 proportional band setting, SV setting and cooling proportional band can be set…

-

Page 33: Out2 (Heating/Cooling Control) Action [Direct (Cooling) Action] (When Setting Dead Band)

11.9 OUT2 (Heating/Cooling control) action [Direct (Cooling) action] (When setting dead band) Cooling P-band Dead band Heating P-band Heating/Cooling control can be used (Cooling Heating Control action by adding Heating/Cooling control action) action option. SV setting Heating proportional band can be Relay contact set during [6] OUT1 proportional output (OUT1)

-

Page 34: Sv Rise Rate, Sv Fall Rate Setting Action

11.11 SV rise rate, SV fall rate setting action [46] SV rise rate and [47] SV fall rate can be set in the Setup mode. (p.21) When the SV is adjusted, it approaches the new SV by the preset SV rise rate or SV fall rate. When SV is adjusted while SV is rising (or falling), SV at the given time becomes a starting point, and approaches the new SV.

-

Page 35

When power is turned on or when control output OFF function is cancelled by the key, SV changes as follows in relation to PV. (e.g.) SV=200 , SV rise rate=6 /Min, SV fall rate=30 /Min [When SV>PV] Temperature SV=200 SV display 200 C (on the SV display) approaches by the SV rise rate. -

Page 36: Communication

Serial communication and Tool port communication cannot be used together. When performing Serial communication, remove the tool cable (AKT4H820) from the USB port of the PC and tool connector of the KT4H/B. When performing Tool port communication, it is not required to remove the Serial communication cables.

-

Page 37

Do not connect a terminator with the communication line because each KT4H/B has built-in pull-up and pull-down resistors instead of a terminator. Even though a terminator is not necessary for communication between the PLC and KT4H/B, if a terminator is required due to signal reflection, connect the terminator on the PLC side. -

Page 38: Communication Parameter Setting

12.3 Communication parameter setting Set each parameter following the procedures below. Setting item numbers such as [17, [19], etc. are the same as those on the “6.4 Operation flowchart”. (p.12) Proceed to Auxiliary function setting mode. Press key while pressing key in the PV/SV display mode.

-

Page 39: Communication Procedures

12.4 Communication procedures Communication starts with command transmission from the host computer (hereafter Master) and ends with the response of the KT4H/B (hereafter Slave). Master Slave • Response with data Command When the master sends the reading command, the slave Data responds with the corresponding set value or current status.

-

Page 40: Mewtocol

(23H) (25H) (Decimal) (0DH) (Decimal) (*) (Decimal) (*) (*): KT4H/B cannot read plural word data. Make sure that both top data items are the same. Acknowledgement Command Reading Address code top data (25H) (Decimal) (24H)

-

Page 41

$ (24H) Response (Normal) ! (21H) Response (Error) Command code: RD; Word data reading (Continuous reading of plural data from the KT4H/B is impossible.) WD; Word data writing (Continuous writing of plural data to the KT4H/B is impossible.) Data code : ASCII code D (44H) is used. -

Page 42

12.5.4 Message example (1) Reading (Address 1, PV) • RD (Word data reading) command from the master Command Data Top data item Top data item Address code code (Decimal) (Decimal) (Decimal) 00356 00356 25H 30H 31H 23H 52H 44H 44H 30H 30H 33H 35H 36H 30H 30H 33H 35H 36H 35H 35H 0DH •… -

Page 43

MEWTOCOL Data item Data command code Use in the system DT00100 (Never use WD command. If WD command is sent to the KT4H/B, the KT4H/B may not be operable.) RD/WD DT00102 Set value, Decimal point ignored 0000H: Cancel RD/WD DT00106… -

Page 44

MEWTOCOL Data item Data command code RD/WD DT00202 SV rise rate Set value, Decimal point ignored RD/WD DT00204 SV fall rate Set value, Decimal point ignored RD/WD DT00210 Control output OUT/OFF 0000H: Control output ON 0001H: Control output OFF RD/WD DT00212 Auto/Manual control 0000H: Automatic control… -

Page 45

MEWTOCOL Data item Data command code RD/WD DT00260 Backlight 0000H: All are backlit 0001H: Only PV display is backlit 0002H: Only SV display is backlit 0003H: Only action indicators are backlit 0004H: PV+SV displays are backlit 0005H: PV+ action indicators are backlit 0006H: SV+ action indicators are backlit RD/WD DT00262… -

Page 46

MEWTOCOL Data item Data command code DT00422 Instrument specification flag 0000 0000 0000 0000 : Contact input 0: Not added, 1: Added : Serial communication 0: Not added, 1: Added : Heater burnout alarm 0: Not added, 1: Added : Heater burnout alarm rating 0: 20A, 1: 50A : Heater burnout alarm specification 0: Single phase, 1: 3-phase : Alarm 2 output… -

Page 47: Modbus Protocol

12.6 Modbus protocol 12.6.1 Transmission mode There are 2 transmission modes (ASCII and RTU) in Modbus protocol. 12.6.2 ASCII mode Hexadecimal (0 to 9, A to F), which is divided into high order (4-bit) and low order (4-bit) out of 8-bit binary data in command is transmitted as ASCII characters.

-

Page 48

(2) Error check of ASCII mode After calculating LRC (Longitudinal Redundancy Check) from the slave address to the end of data, the calculated 8-bit data is converted to two ASCII characters and are appended to the end of message. How to calculate LRC Create a message in RTU mode. -

Page 49

Reading (Address 1, SV) • A request message from the master The number of data means the data item to be read, and it is fixed as 1 (30H 30H 30H 31H). Header Slave Function Data item Number of data Error check Delimiter address… -

Page 50

12.6.2 RTU mode 8-bit binary data in command is transmitted as it is. Data format Start bit : 1 bit Data bit : 8 bits Parity : No parity (Even, Odd) Selectable Stop bit : 1 bit (2 bits) Selectable Error detection: CRC-16 (Cyclic Redundancy Check) Data interval : 3.5 character transmission time or less (1) Message configuration… -

Page 51

(2) Error check of RTU mode After calculating CRC-16 (Cyclic Redundancy Check) from the slave address to the end of data, the calculated 16-bit data is appended to the end of message in sequence from low order to high order. How to calculate CRC In the CRC system, the information is divided by the polynomial series. -

Page 52

Reading (Address 1, SV) • A request message from the master The number of data means the data item to be read, and it is fixed as 1 (0001H). Slave Function Data item Number of data Error check 3.5 idle 3.5 idle address code… -

Page 53

Data item Data function code Use in the system 0000H (Never use function code 06H. If function code 06H is sent to the KT4H/B, the KT4H/B may not be operable.) 03H/06H 0001H Set value, Decimal point ignored 0000H: Cancel 03H/06H… -

Page 54

Modbus Data item Data function code 03H/06H 0033H SV rise rate Set value, Decimal point ignored 03H/06H 0034H SV fall rate Set value, Decimal point ignored 0000H: Control output ON 03H/06H 0037H Control output OUT/OFF 0001H: Control output OFF 0000H: Automatic control 03H/06H 0038H Auto/Manual control… -

Page 55

Modbus Data item Data function code 03H/06H 0050H Backlight 0000H: All are backlit 0001H: Only PV display is backlit 0002H: Only SV display is backlit 0003H: Only action indicators are backlit 0004H: PV+SV displays are backlit 0005H: PV+ action indicators are backlit 0006H: SV+ action indicators are backlit 03H/06H 0051H… -

Page 56

Modbus Data item Data function code 00A1H Instrument specification flag 0000 0000 0000 0000 : Contact input 0: Not added, 1: Added : Serial communication 0: Not added, 1: Added : Heater burnout alarm 0: Not added, 1: Added : Heater burnout alarm rating 0: 20A, 1: 50A : Heater burnout alarm specification 0: Single phase 1: 3-phase : Alarm 2 output 0: Not added, 1: Added… -

Page 57: Specifications

13. Specifications 13.1 Standard specifications Mounting : Flush Setting : Input system using membrane sheet key Display PV display : 11-segment backlight LCD Red/Green/Orange, character size 12.0 x 5.4mm (H x W) SV display : 11-segment backlight LCD Green, character size 6.0 x 3.5mm (H x W) MEMO display : 11-segment backlight LCD Green, character size 4.8 x 2.8mm (H x W) : Backlight Orange Action indicators…

-

Page 58

(Depth of control panel interior when rubber gasket is not used: 56.0mm) Material : Flame resistant resin (Case) Color : KT4H: Ash gray (Case) KT4B: Black (Case) Attached functions: [Power failure countermeasure] The setting data is backed up in the non-volatile IC memory. -

Page 59

PV/SV display mode. Auto/Manual control can be switched. [Tool port communication] By connecting to the tool connector of the KT4H/B, the following operations can be conducted from the external computer. (1) Reading and setting of SV, PID and various set values… -

Page 60: Optional Specifications

Accessories included: Mounting frame 1 piece Rubber gasket (Front mounted to the KT4H/B) 1 piece Installation instructions (A3 unfolded, English/Japanese) 1 copy Communication installation instructions (When Serial communication option is added) 1 copy CT (Current transformer) CT1 (AKT4815) (When Heater burnout alarm Single phase 20A option is added) 1piece…

-

Page 61

Serial communication Cannot be used with Tool port communication. If this option is added, Contact input option cannot be added. The following operations can be carried out from the external computer. (1) Reading and setting of the SV, PID values and various set values (2) Reading of the PV and action status (3) Function change Communication line : EIA RS-485… -

Page 62: Troubleshooting

14. Troubleshooting If any malfunctions occur, refer to the following items after checking the power supply to the controller. 14.1 Indication Problem Presumed cause and solution • Control output OFF function is working. ] is indicated on the PV Press the key for approx.

-

Page 63: Key Operation

• Check whether the input lead wire terminals for DC voltage (0 to 5V DC, 0 to 10V DC) or DC current (0 to 20mA DC) are securely mounted to the instrument input terminals. The indication of PV display is •…

-

Page 64: Communication

• The setting command data exceeds the setting range of the slave. “NAK”. • The controller cannot be set when functions such as AT are performing. • The KT4H/B is in the front key operation setting mode. For all other malfunctions, please contact our main office or dealers.

-

Page 65: Revision History

Revision History Issue Date Manual no. Content of revision May, 2005 ARCT1F412E First edition October, 2005 ARCT1F412E-1 edition P.14 P.15 P.16 P.18 Addition of explanation in detail P.19 P.20 P.21 April, 2007 ARCT1F412E-2 edition Addition of explanation in detail P.32~33 Addition of explanation in detail P.34~35 Addition of explanation of “SV rise…

Communication Installation Instructions KT4H/B TemperatureController

These instructions are for communication functions. For detailed operating

instructions, please refer to User’s Manual for the KT4H/B.

Serial communication and Toolport communication cannot be used together.

When performing Serial communication, remove the tool cable (AKT4H820) from

the USB port of the PC and tool connector of the KT4H/B.

When performing Tool port communication,it is not required to remove the Serial

communication cables. However,do not send a command from the master side.

No. KT4HCE4 2009.11

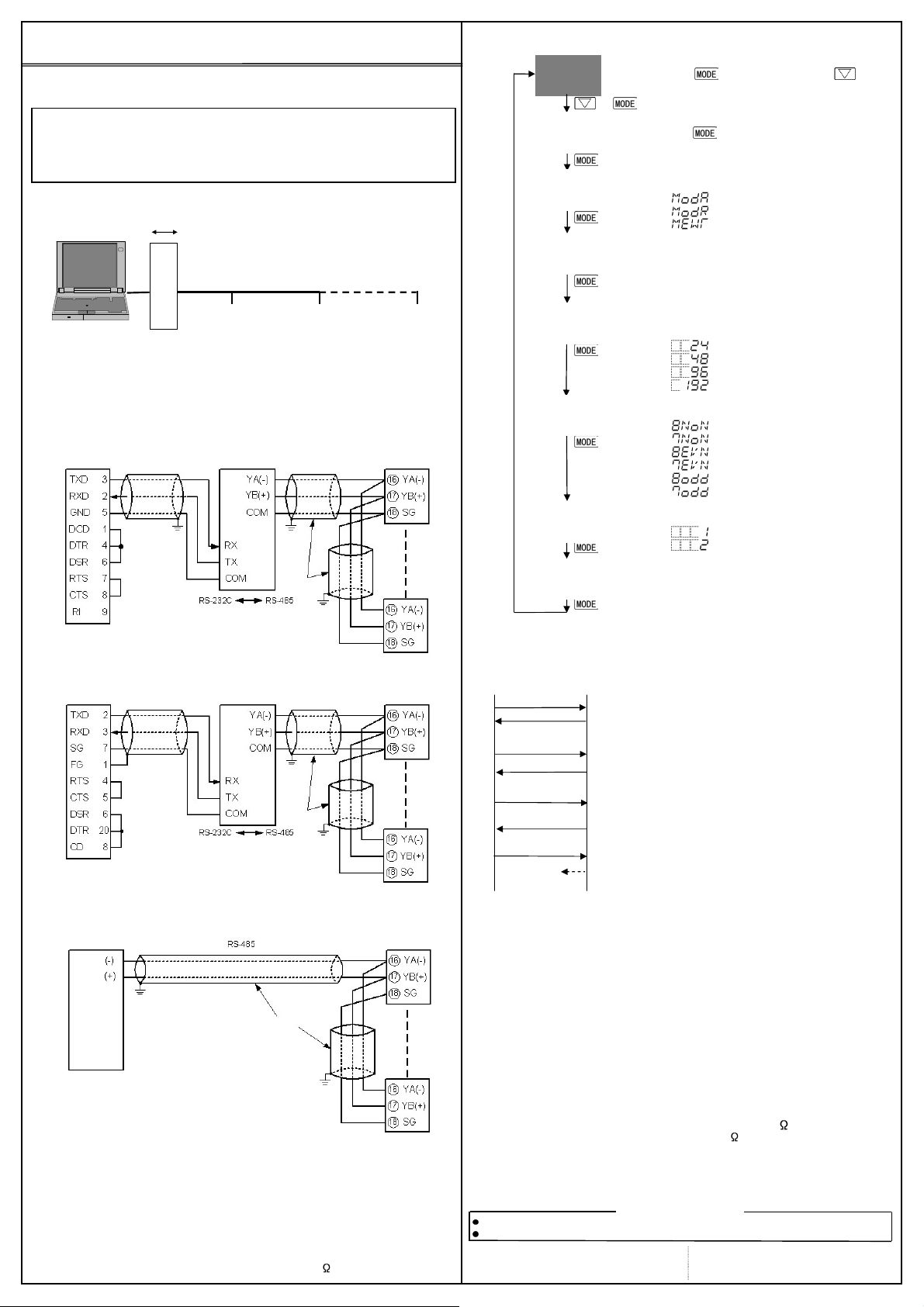

5. System configuration

Communicationconverter

RS-232C RS-485

No. 1 No. 2 No. 31

Host computer

(Fig. 1-1)

KT4H or KT4B

2. Wiring

Wiring example using a communication converter

Using a D-sub 9-pin Connector

Host computer

wire

FG

D-sub 9-pin connector

Using a D-sub 25-pin Connector

Hostcomputer

wire

D-sub 25-pin connector

When connecting to a PLC (RS-485)

PLC

FG

Shieldedwire

Connectonlyone sideoftheshieldedwire to the FG terminalsothatcurrentcannot

flowto the shielded wire.If both sidesofthe shielded wire are connected to the FG

terminal, the circuit will be closedbetween the shielded wire and the ground. As a

result, current will run through the shielded wire and this may cause noise.Be sure

togroundthe FG terminal.

Terminator(Terminal resistor)

Do not connect terminator with the communicationline because each KT4H/B has

built-inpull-upandpull-downresistorsinsteadof aterminator.

If there is a large distance between the PLC and the KT4H/B, connect the

terminator on the PLC side.(Connecta terminatorof120 ormoreresistance.)

(Fig. 2-1)

(Fig. 2-2)

(Fig. 2-3)

FG

wire

FG

FG

wire

FG

Shielded wire

FG

KT4H or KT4B

KT4H or KT4B

KT4H or KT4B

3. Communication parameter setting

Set each communication parameter following the procedures below.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Numbers such as [17], [19], etc. are setting item numbers.

Refer to the User’s Manual for the KT4H/B.

+

(Twice)

Proceed to Auxiliary function setting mode.

Press key while pressing key in

the PV/SV display mode. The unit proceeds

to Auxiliary function setting mode.

Auxiliary function setting mode

Press key twice.

The unit proceeds to Communication protocol

selection.

Communication protocol selection

Select the communication protocol.

Instrument number setting

Set the instrument number of the controller

individually when communicating by connecting

plural instruments.

Communication speed selection

Set the communication speed equal to that of

the host computer.

Data bit/Parity selection

Select the data bit and parity.

Stop bit selection

Select the stop bit.

Communication response time setting

Set the minimum response time.

5 to 99 (Default: 5ms)

: Modbus ASCII mode (Default)

: Modbus RTU mode

: MEWTOCOL (Slave)

1 to 99 (Default: 1)

: 2400bps

: 4800bps

: 9600bps (Default)

: 19200bps

: 8 bits/No parity

: 7 bits/No parity

: 8 bits/Even

: 7 bits/Even (Default)

: 8 bits/Odd

: 7 bits/Odd

: 1 (Default)

: 2

4. Communication procedures

Communication starts with command transmission from the host computer

(Master) and ends with the response of the KT4H/B (Slave).

Master Slave

Command

Data

Command

Acknowledgement

Command

Acknowledgement

Command

Noresponse

(Fig.4-1)

RS-485 communication timing

Master side (Notice on programming)

Set the program so that the master can disconnect the transmitter from the

communication line within a 1 character transmissionperiod after sending the

command in preparation for reception of the response from the slave.

To avoid the collision of transmissions between the master and the slave, send

thenextcommand aftercarefullychecking thatthemasterreceivedthe response.

Slave side

When the slave starts transmission through the communication line, the slave

is arranged so as to provide an idle status(mark status)transmission period of

5ms or more (communication response time from 5 to 99ms settable) before

sending the response to ensure the synchronization on the receiving side.

Theslaveis arrangedso as todisconnect the transmitterfrom thecommunication

line within a 1 character transmission period after sending the response.

• Response with data

When the master sends the reading command, the

slave responds with the corresponding set value or

current status.

• Acknowledgement

When the master sends the setting command, the

slave responds by sending the acknowledgement

after the processing is terminated.

• Negative acknowledgement

When the master sends non-existent command or

value out of the setting range, the slave returns the

negative acknowledgement.

• No response

Theslavewillnotrespondtothemasterinthefollowing cases.

• Global address “FF” (MEWTOCOL) is set.

• Broadcast address (Modbus protocol) is set.

• Communication error (framing error,parity error)

• LRC discrepancy (Modbus ASCII mode)

• CRC-16 discrepancy (Modbus RTU mode)

5. Specifications

Communicationsystem: Half duplex

Cable length : 1,000m (Max.), cable resistance 50 or less

Communicationline :EIARS-485

Communicationspeed : 9600bps(2400,4800,9600,19200bps) Selectablebykey

Synchronoussystem :Start-stopsynchronous

Code :ASCII(ModbusASCII,MEWTOCOL),Binary(ModbusRTU)

Errorcorrection :Commandrequestrepeatsystem

PleasedownloadUser’sManualathttp://panasonic-denko.co.jp/ac/e/

ForthedetailedusageandUser’sManual,pleasecontactusat theaddressbelow.

Panasonic E lectric Works Co., Ltd. Automation Controls Business U nit

HeadOffice:1048Kadoma,Kadoma-shi,Osaka571-8686,Japan Panasonic Electric Works Europe AG

Telephone: Japan (81) Osaka (06) 6908-1050 Rudolf-Diesel-Ring 2 83607 Holzkirchen, Germany

Facsimile : Japan (81) Osaka (06) 6908-5781 Thisproducthasbeendeveloped/producedfor industrialuseonly.

(Terminator: None or 120 or more on PLC side)

AboutUser’sManual

Pursuant to the directive 2004/108/EC, article 9(2)

InstallationInstructions KT4H/B TemperatureController

contact with the controller

Forapprox.3secondsafterthepoweristurnedon,thePVdisplayindicatesthe

indicates input range high limit value (TC, RTD

Thismeansthatif MODEkeyispressed,

To ensure safeand correctuse,thoroughlyreadandunderstandthese instructionsbeforeusing

thisinstrument.Fordetailedusageandoptions,pleaserefertoUser’sManualfortheKT4H/B.

SAFETY PRECAUTIONS

(Besuretofollowtheprecautionsdescribedbelowtopreventinjuryoraccidents.)

Thesafetyprecautionsareclassifiedintocategories:“Warning”and“Caution”.

Warning:Procedures whichmayleadto dangerousconditionsand causedeathor

seriousinjury,if notcarriedoutproperly.

Caution:Procedureswhichmayleadtodangerousconditionsandcausesuperficial

to medium injury or physical damage or may degrade or damage the

product,ifnotcarriedoutproperly.

• When using this controller on occasions which serious injury would be expected to

occur or when damage is likely to expand or proliferate, make sure to take safety

measuressuchasinstallingdoublesafetystructures.

• Do not use this controllerin an environment with flammable gases, or it may cause

explosion.

Warning

No. KT4HE5 2009.07

Caution

•Fasten the electric wire withthe terminalscrews securely. Imperfectconnectionmay

causeabnormalheatingorfumes.

• Use this controller according to the rating and environmental conditions. Otherwise

abnormalheatingorfumesmay occur.

• Do not touch the terminals while the power is supplied to the controller, as thismay

causeelectricshock.

•Do notdisassembleor modifythecontroller, asthismaycauseelectricshockorfumes.

Caution

• This instrument should be used in accordance with the specifications described in these

instructions.Ifitisnotusedaccordingtothespecifications,itmaymalfunctionorcausefire.

•Be suretofollowthewarnings,cautionsandnotices.Notdoingsocouldcauseserious

injuryoraccidents.

•Thecontents ofthisbookletaresubjectto changewithout notice.

• This instrumentisdesignedto beinstalledina controlpanel.Ifnot,measuresmustbe

taken to ensure that the operator cannot touch powerterminals or other highvoltage

sections.

•Be suretoturnthepowersupplyto theinstrumentOFFbeforecleaningthisinstrument.

•Use asoft,dryclothwhencleaningtheinstrument.

(Alcoholbasedsubstancesmaytarnishor defacetheunit.)

•Asthedisplaysectionisvulnerable, donotstrikeor scratchit witha hardobject.

•Anyunauthorizedtransferor copyingof thisdocument,inpartorin whole,isprohibited.

• Matsushita Electric Works, Ltd. is not liable for anydamages or secondary damages

incurredasa resultof usingthisproduct,includinganyindirect damages.

2.2 External dimensions (Unit: mm) Common to KT4H/B

2.3 Panel cutout (Unit: mm)

(Fig. 2.3-1)

2.4 Mounting and removal to/from the control panel

How to mount the KT4H/B (Fig.2.4-1, Fig.2.4-2)

MountthecontrollerverticallytoensureitadherestotheDust-proof/Drip-proofspecification(IP66).

Mountablepanelthickness:Within1 to 5mm

(1)Insertthecontrollerfromthefrontsideofthepanel.

(2)Insertthemountingframeuntiltheframetipscomeintocontactwiththepanel,andfastenwithscrews.

Tightenscrewswithonerotationuponthescrewtipstouchingthepanel.Torque:0.05to0.06N•m.

How to remove the mounting frame (Fig.2.4-3)

(1)TurnthepowertotheunitOFF, anddisconnectallwiresbeforeremovingthemountingframe.

(2) Insert a flat blade screwdriver between the screw frame and unit1.

(3)Slowlypushtheframeupwardusingthescrewdriver2whilepushingtheunittowardthepanel3.

(4) Repeat step (2) and slowlypushtheframedownwardusingthescrewdriverfor the other side.

The frame can be removed little by little by repeating these steps.

75

Rubbergasket

+0.5

45

0

Mounting frame

Mountingframe

0

+0.5

45

n×48-3

Lateralclose mounting,n: Number of units mounted

Caution: If lateral close mounting is used

for the controller, IP66 (Dust-proof/Drip-proof)

may be compromized, and all warranties will

be invalidated.

1. Name and functions of the sections

KT4H or KT4B

PV display

MEMO display

MODE key

OUT/OFF key

MODE key : Selects the setting mode, or registers the set value.

OUT/OFF key : Switches control output ON/OFF or Auto/Manual control.

Increase key :Increases the numeric value.

Decrease key : Decreases the numeric value.

PV display : Indicates the PV (process variable).

SV display : Indicates the SV (main set value).

MEMO display : Indicates the set value memory number.

Action indicators

: Temperature unit or lights when selected.

T/R : Lights when Serial communication (option) is performing (TX output).

AT : Flashes whileAT(auto-tuning) or auto-reset is performing.

OUT1: Lights when control output is ON or when Heating output (option) is ON.

Flashes corresponding to the MV in 0.25 second cycles for DC current output type.

OUT2: Lights when cooling output (option) is ON.

EVT1 : Lights when Alarm 1 output is ON.

EVT2 : Lights when Alarm 2 output (option) is ON or Heater burnout alarm (option) is ON.

LOCK: Lights when Lock 1, Lock 2 or Lock 3 is selected.

Tool connector: The following operations can be conducted from external computer by

connecting the tool cable (sold separately). (1) Reading and setting of SV, PID and

2. Mounting to the control panel

2.1 Site selection

0

various set values, (2) Reading of PV and action status, (3) Function change

This instrument is intended to be used under the following environmental conditions

(IEC61010-1): Overvoltage category , Pollution degree 2

Ensure the mounting location corresponds to the following conditions:

• A minimum of dust, and an absence of corrosive gases

• No flammable, explosive gases

• Few mechanical vibrations or shocks

• No exposure to direct sunlight, an ambient temperature of 0 to 50 (32 to 122 ) that

does not change rapidly

• An ambient non-condensing humidity of 35 to 85%RH

• No large capacity electromagnetic switches or cables through which large current is flowing

• No water,oil or chemicals or where the vapors of these substances can come into direct

(Fig.1-1) (Fig.1-2)Bottomview

SV display

Increase key

Decrease key

(Fig. 2.4-1)

(Fig. 2.4-2)

3. Wiring

Turnthe powersupplyto the instrument offbeforewiringor checking it.

Working or touching the terminal with the power switched on may result in

severe injuryor death dueto Electric Shock.

Warning

Caution

•Theterminalblockof thisinstrumentisdesignedtobe wiredfromtheleftside.

Thelead wiremust be insertedfrom the leftside of the terminal, and fastened by

theterminalscrew.Thetorqueisapproximately0.63N•m.

• When using a terminalcover(AKT4H801),pass terminal wires numbered 7 to12

intotheholesoftheterminalcover.See(Fig.3-2).

•To extend a thermocouple’s lead wire, be sure to use a compensating lead

wire in accordance with the sensor input specification. (If any other compensating lead wire is used, a temperature indication error may be caused.)

•Usethe3-wireRTDwhichcorrespondstotheinputspecificationofthiscontroller.

•Thiscontrollerdoesnothavea built-inpowerswitch,circuitbreakerorfuse.

Therefore,itisnecessarytoinstalltheminthecircuitneartheexternalcontroller.

(Recommendedfuse:Time-lag fuse,ratedvoltage250VAC,ratedcurrent2A)

•Fora24VAC/DCpowersource,donotconfusepolaritywhenusingdirectcurrent(DC).

• When using a relay contact output type, externally use a relay according to the

capacityoftheloadto protectthebuilt-inrelaycontact.

•When wiring,keepinputwires (thermocouple,RTD,etc.) away from ACsourcesor

loadwirestoavoidexternalinterference.

• If Alarm 2 and Heater burnout alarm are added together, they (EVT2) utilize

commonoutputterminals.

Lead wire solderless terminal Whenusing aTerminalcover

Usea solderlessterminalwithaninsulationsleevein whichanM3 screw

fitsas shownbelow.The torqueis approximately0.63N•m.

Solderless

terminal

Ytype

type

Manufacturer

NichifuTerminalIndustriesCo.,Ltd. TMEV1.25Y-3

JapansolderlessTerminalMFGCo.,Ltd. VD1.25-B3A

NichifuTerminalIndustriesCo.,Ltd. TMEV1.25-3Round

JapanSolderlessTerminalMFGCo.,Ltd. V1.25-3

5.8mmorless

Model

name

5.8mmorless

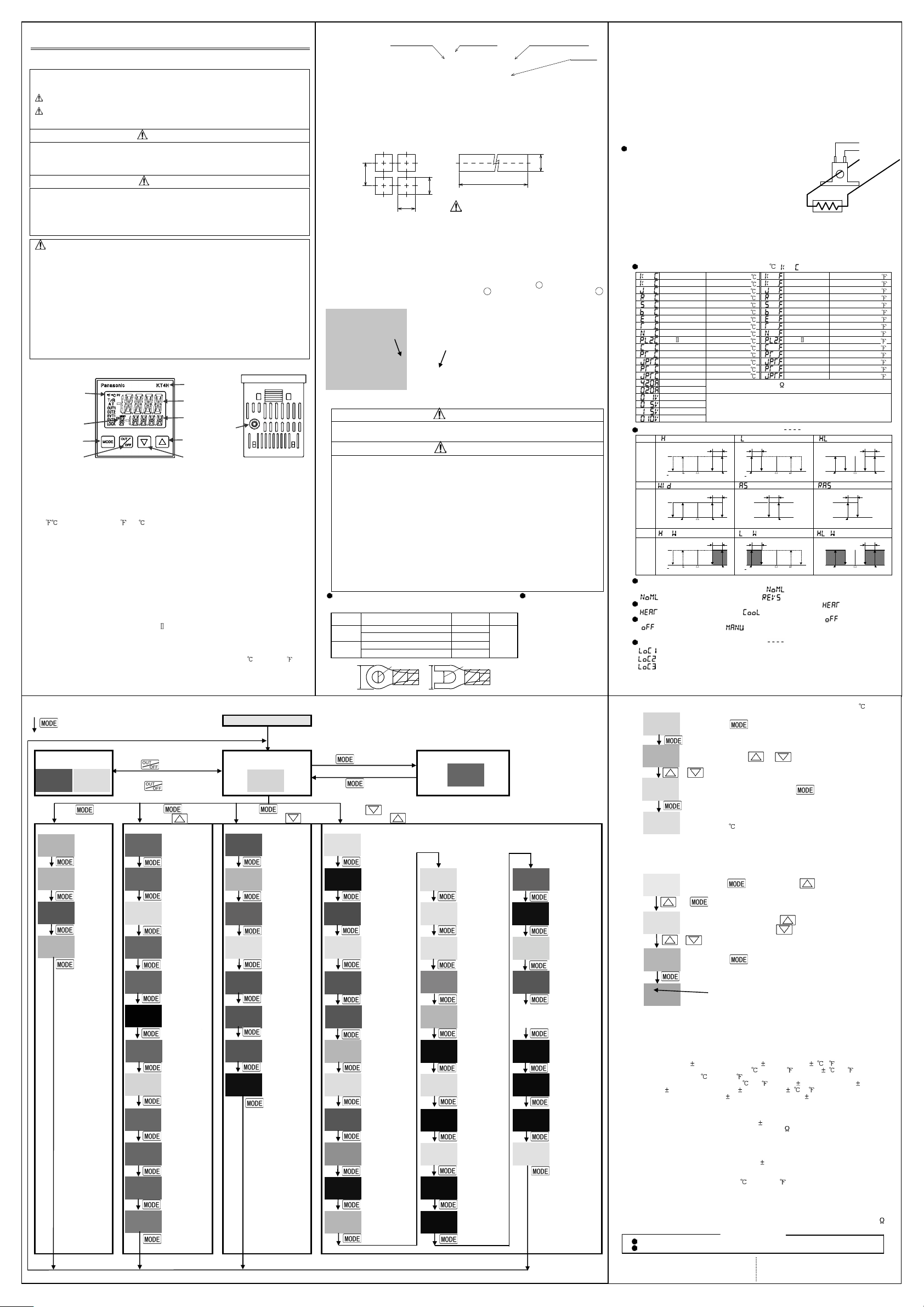

5. Operation flowchart

theunitproceedstothenextsettingmode.

ControloutputOFF

/Manualcontrol

ForControloutputOFF,

press keyforapprox.1sec.

Power ON

PV/SVdisplaymode

(Automaticcontrol)

ForAuto/Manualcontrol,

press key.

Press key. Press keywhile

Main setting mode Sub setting mode Auxiliaryfunctionsettingmode Setup mode

(*): Setting items with (*) are optional, and they appear only when the options are added. Numbers suchas [1], [2],etc.are settingitemnumbersin the User’s Manual.

SV AT/Auto-reset

SV2

(*)

SV3

(*)

SV4

(*)

pressing key.

Perform/Cancel

OUT1

proportional

band

OUT2

proportional

band(*)

Integral time Instrument

Derivative time Communication

ARW Data bit/Parity

OUT1

proportional

cycle

OUT2

proportional

cycle (*)

Alarm 1 value OUT2 action

Alarm 2 value

(*)

Heater burnout

alarm value (*)

Heater burnout

alarm 2 value(*)

Press keyforapprox.3sec. Press keyforapprox.3sec.

whilepressing key. whilepressing key.

Set value

locks

Sensor

correction

Communication

protocol (*)

number (*)

speed (*)

(*)

Stop bit (*) OUT1 low limit Alarm 1

Communication

response time

(*)

inputtype, and the SV display

input)orscalinghighlimitvalue(DCvoltage,DCcurrentinput).

Output MV indication

Press key.

Input type

Scaling

high limit

Scaling

low limit

Decimal point

place

PV filter time

constant

OUT1 high limit Alarm2Energized/

OUT1 ON/OFF

action hysteresis

mode selection(*)

OUT2 high limit

(*)

OUT2 low limit

(*)

Overlap/Dead

band (*)

OUT2 ON/OFF

action hysteresis

(*)

Alarm 1 type ATbias

Alarm 2 type

(*)

Alarm1Energized

/Deenergized

Deenergized (*)

hysteresis

Alarm 2

hysteresis (*)

Alarm 1 action

delayed timer

Alarm 2 action

delayed timer (*)

SV rise rate

SV fall rate

Terminalcover(soldseparately)

+0.5

0

Tightening

torque

0.63N•m

M3 screw

(Fig. 2.2-1)

0

+0.5

45

(Fig. 2.4-3)

(Fig. 3-2)

Direct/Reverse

control

Contact input

function (*)

Output status

selectionwheninput

abnormal

OUT/OFF key

function

Backlight

PV color

PV color range

Backlight time

EVT2 : Alarm 2 output (option) or

Heater burnout alarm output

(option)

OUT1 : Control output or Heating

output (option)

OUT2 : Cooling output (option)

TC : Thermocouple input

RTD : RTD input

DC : DC current, voltage input

CT1 : Current transformer input

(option: Single, 3-phase)

CT2 : Current transformer input

(option: 3-phase)

RS-485: Serial communication (option)

DI : Contact input (option)

Wiring of Heater burnoutalarm (single,3-phase)

Thisalarmisnotusablefordetectingheatercurrentunderphasecontrol.

Usethecurrenttransformer(CT)provided,andpassoneleadwireof the

heatercircuitintotheholeof theCT.(Fig.3-4)Whenwiring,keeptheCT

wireawayfromACsourcesorloadwirestoavoidtheexternalinterference.

Inthecaseof 3-phase,passany2 leadwiresofR,S,TintotheCT,

andconnectthemwithCT1(13,14)andCT2(14,15)terminals.

4. Operation

After the unit is mounted to the control panel and wiring is completed, operate the unit

following the procedures below.

(1) Turn the power supply to the KT4H/B ON.

(2) Initial settings

Refer to “5. Operation flowchart”, “6. Basic operation” and “7. AT Perform/Cancel”.

Select an input type, alarm type, Direct/Reverse action, etc. during Setup mode.

If initial settings are not required, skip this step, and proceed to step (3).

Input type selection (Default: K, -200 to 1370 )

Alarm type selection (Default: No alarm action “ ”)

Alarm

action

Alarm

action

Alarm

action

Alarm Energized/Deenergized selection

[Default: EVT1contactoutputON(Energized) ]

Direct/Reverse action selection [Default: Reverse (Heating) ]

OUT/OFF key function selection (Default: OUT/OFF function )

(3) Input each set value. Referto chapters“5. Operationflowchart” and “6.Basic operation”.

Set value lock selection (Default: Unlock )

(4) Turn the load circuit power ON.

Control action starts so as to keep the control target at the SV (desired value).

(1) Proceed to the Main setting mode.

(2) Set SV.

(3) Register the SV.

(4)

7. AT Perform/Cancel (PID action)

Inordertoset each valueof P,I, DandARW automatically,theauto-tuningprocessshouldbe madeto

fluctuatetoobtainan optimalvalue. Sometimestheauto-tuningprocesswillnotfluctuateif auto-tuning

isperformedator nearroomtemperature. Thereforeauto-tuning mightnotfinishnormally.

(1)

(2)

(3)

(4)

Auto-reset can be performed during P or PD action. Auto-reset is cancelled in approximately

4 minutes. It cannot be released while performing this function.

8. Specifications

Power supply: 100 to 240VAC 50/60Hz, or 24V AC/DC 50/60Hz

Indication accuracy

Thermocouple:Within 0.2%ofeachinputspan 1digit, or within 2 (4 ), whicheveris greater

However, for R, S inputs, 0 to 200 (0 to 400 ): Within 6 (12 )

B input, 0 to 300 (0 to 600 ): Accuracy is not guaranteed.

K, J, E, T, N inputs, less than 0 (32 ): Within 0.4% of input span 1digit

RTD: Within 0.1%of each inputspan 1digit,orwithin 1 (2 ),whicheveris greater

DC current, voltage input: Within 0.2% of each input span 1digit

Control output 1

Relaycontact:1a,Controlcapacity, 3A250VAC(resistiveload) 1A250VAC(inductiveloadcosø=0.4)

Non-contact voltage (for SSR drive): 12V DC 15% Max. 40mA (short circuit protected)

DC current: 4 to 20mADC, Load resistance, Max. 550

Alarm 1 output, Alarm 2 output, Heater burnout alarm output

Relay contact 1a, Control capacity, 3A 250V AC (resistive load), Electric life, 100,000 cycles

Control output 2

Relay contact 1a, Control capacity, 3A 250V AC (resistive load), Electric life, 100,000 cycles

Non-contact voltage (For SSR drive): 12V DC 15%,Max. 40mADC (short circuit protected)

Contact input : Circuit current when closed: Approx. 6mA

Power consumption : Approx. 8VA

Ambient temperature, humidity: 0 to 50 (32 to 122 ), 35 to 85%RH (no condensation)

Weight : Approx. 120g

Accessories included: Mounting frame 1 piece, Rubber gasket (Mounted to the unit) 1 piece,

Heater burnout alarm Single phase 20A:CT1(AKT4815),50A:CT2(AKT4816):1 pieceeach

Heater burnout alarm 3-phase 20A:CT1(AKT4815),50A:CT2(AKT4816):2pieceseach

Accessories sold separately: Terminal cover (AKT4H801), Shunt resistor [AKT4810 (50 )]

Please download User’s Manual at http://www.nais-e.com/download/index.html

For the detailed usage and User’s Manual, please contact us at the address below.

PanasonicElectricWorksCo.,Ltd.AutomationControlsBusinessUnit

HeadOffice :1048Kadoma,Kadoma-shi,Osaka571-8686,Japan PanasonicElectric Works Europe AG

Telephone : Japan (81) Osaka (06) 6908-1050 Rudolf-Diesel-Ring 2 83607 Holzkirchen, Germany

Facsimile :Japan (81) Osaka (06) 6908-5781 Thisproducthasbeendeveloped/producedforindustrialuseonly.

(Fig. 3-3)

CT

Heater

K -200 to 1370 K -320 to 2500

K -200.0 to 400.0 K -320.0 to 750.0

J -200 to 1000 J -320 to 1800

R 0to 1760 R 0 to 3200

S 0 to 1760 S 0 to 3200

B 0 to 1820 B 0 to 3300

E -200 to 800 E -320to 1500

T -200.0 to 400.0 T -320.0to 750.0

N -200to 1300 N -320 to 2300

PL- 0 to 1390 PL- 0to 2500

C(W/Re5-26) 0 to 2315 C(W/Re5-26) 0 to 4200

Pt100 -200.0 to 850.0 Pt100 -320.0to 1500.0

JPt100 -200.0 to 500.0 JPt100 -320.0 to 900.0

Pt100 -200 to 850 Pt100 -320 to 1500

JPt100 -200 to 500 JPt100 -320 to 900

4 to 20mA

0 to 20mA

0 to 1V

0 to 5V

1 to 5V

0 to 10V

ON

OFF

A1

setpoint

High/Lowlimitrangealarm

ON

OFF

A1

setpointA1setpoint

ON

OFF

A1

setpoint

:EVT1contactoutputON(Energized) :EVT1contactoutputOFF(Deenergized)

: Reverse action (Heating), : Direct action (Cooling)

: OUT/OFF function, :Auto/Manual control function

: Lock 1 (All set values are locked)

: Lock 2 (All set values except SV are locked)

: Lock 3 (Set values can be changed temporarily,however, after the power is

and

or

Allowable fluctuation range: 100 to 240V AC: 85 to 264VAC,

Electric life: 100,000 cycles

-2000 to 10000 [Connect 50 shuntresistor (AKT4810,soldseparately).]

-2000 to 10000

High limit alarm

A1 hysteresis

SV

+A1

setting

set point

A1 hysteresis

SV

setting

High limit alarm

with standby

A1 hysteresis

SV

+A1

setting

set point

turned off and on, they return to their previous values.)

(Main setting mode, When setting SV to 100 )

Press key in the PV/SV display mode.

The unit proceeds to the Main setting mode.

Set SV with or key.

or

Register the SV by pressing key.

The unit reverts to the PV/SV display mode.

Control starts.

Control starts so as to keep the measuring temperature

at 100 .

Proceed to the Sub setting mode.

Press keywhilepressing keyin thePV/SVdisplay

mode.TheunitproceedstotheSubsettingmode.

Select AT Perform/Cancel.

Select ATPerform with key, or

select ATCancel with key.

Confirm AT Perform/Cancel.

Press key.

The unit reverts to the PV/SV display mode.

AT Perform/Cancel

While ATis performing, theAT indicator flashes, and it goes

off when ATis cancelled.

Installation instructions 1 copy

Toolcable (AKT4H820)

AboutUser’sManual

Low limit alarm

A1 hysteresis

ON

OFF

OFF

ON

OFF

SV

A1

setting

setpoint

Process high alarm Process low alarm

ON

A1

setpoint

Low limit alarm

with standby

A1 hysteresis A1 hysteresis

SV

A1

setting

setpoint

24V AC/DC : 20 to 28V AC/DC

Pursuant to the directive 2004/108/EC, article 9(2)

+A1

set point

+A1

set point

ON

OFF

ON

OFF

ON

OFF

setpoint

setpoint

(13)

(14)

Power

supply

High/Lowlimitsalarm

A1 hysteresis

SV

A1

setting

setpoint

A1 hysteresisA1 hysteresis

A1

setpoint

High/Low limits alarm

with standby

SV

A1

setting

setpoint

CT1 input

terminals

A1

A1

Продолжая использовать joom.ru, вы подтверждаете, что согласны с Правилами использования и Политикой конфиденциальности, в том числе, с порядком использования cookie-файлов.

Джум Гик

Домашняя страница Джум

Войти

Мои заказы

Корзина

Товар раскупили

KT4H 0-330 В светодиодный тестер подсветки телевизора, ручная регулировка напряжения, драйвер постоянного тока, ремонт платы, светодиодный шарик(EU Plug)

Магазин

sun shine-7

Электрические тестеры и диагностические инструменты

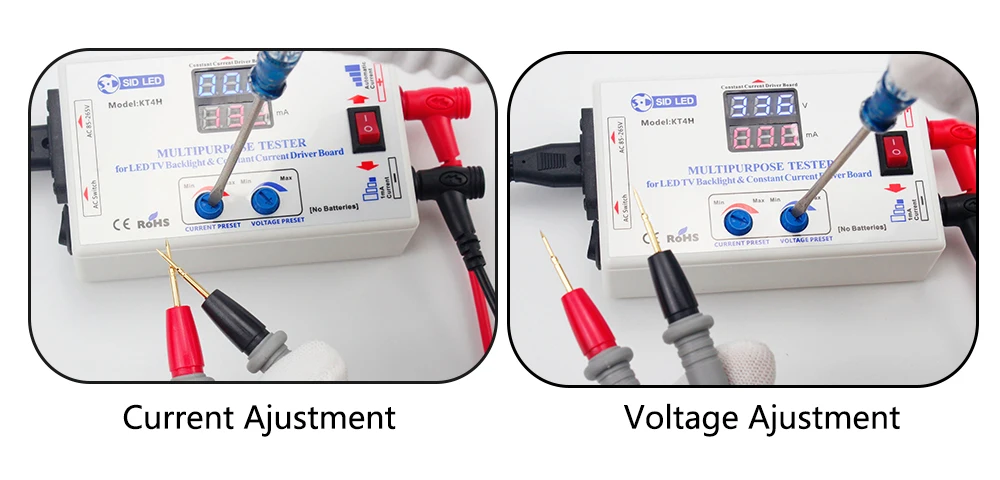

Параметры продукта

• Модель продукта: KT4H• Вин: 85-265 В переменного тока• Выход: постоянный ток 0-330 в (автоматический + регулируемый)• Точность вольтметра по уровню поверхности: < (± 0,5 ± 1% Vout) v-образный вырез• Iout: 0-150 мА (автоматический + регулируемый)• Постоянный ток тестового тока: 0-999 мА• Точность амперметра: <(± 2 ± 1% Iout) mA• Pinput: 50VA (макс.)• Температура: -20 ℃ ~ + 40 ℃

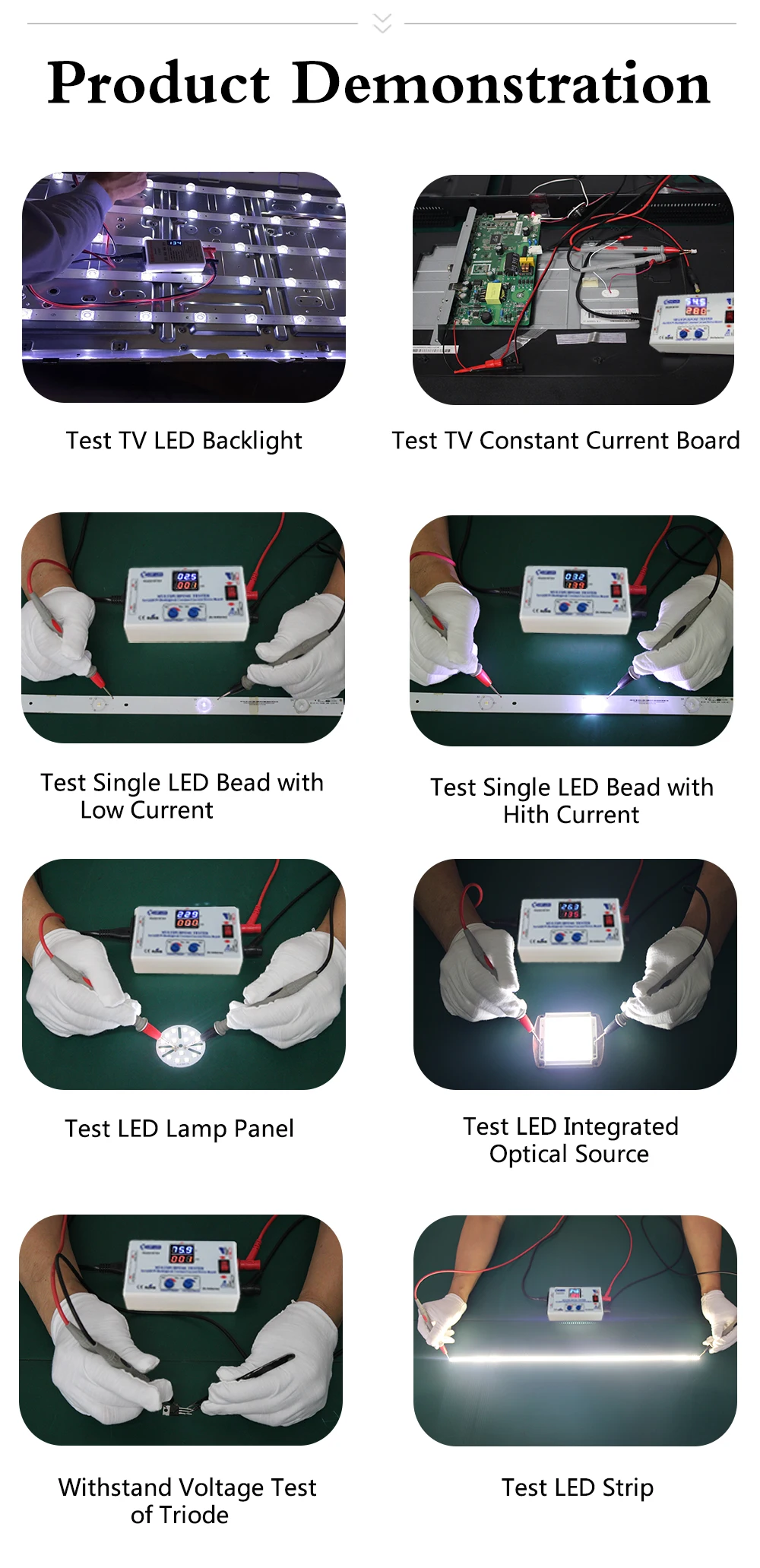

Введение продукта

Тестирование напряжения и тока платы постоянного тока в режиме реального времени.1. Светодиодный тест-полоски, СВЕТОДИОДНЫЙ панели, один светодиодный шарик, источники освещения COB и так далее.2. Тестирование подсветки светодиодный-телевизора, дисплеев, компьютеров и так далее.3. Совместим со всеми светодиодный полоски (высокого напряжения или низкого напряжения).4. Ручная регулировка диапазона испытательного напряжения (20-330 в/постоянный ток) и тока (20-150 мА).Регулировка напряжения при открытой цепи (без нагрузки) и регулировка тока с нагрузками или контактными зондами вместе.5. Не выгорает при тестировании один светодиодный шарик с неправильной полярностью. (Установите напряжение около 20 в и переключатель тока до 1 мА)6. Параметры тестирования напряжения различных электронных компонентов.7. Испытательный светодиодный светильник на транспортном средстве.

Методы тестирования

Заводская установка по умолчанию: выходное напряжение 330 в, выходной ток 30 мА. Вы можете протестировать подсветку телевизора с любым размером в этих настройках по умолчанию.1. Самостоятельное тестирование: Подключите, включите выключатель питания. Напряжение около 330 В, ток 0; Свяжитесь с зондами вместе, изменение напряжения на 0 и изменение тока на около 50 мА, затем можно начать тестирование.2. При тестировании:Напряжение = 0, короткое замыкание.Напряжение = ‘330V’, открытая цепь.3. Тестирование одного светодиодный бусин (Установите напряжение около 20 в и переключатель тока до 1 мА):А. С правильной полярностью: напряжение показывает на тестере нормальный светодиодный шарик составляет около 80% от номинального напряжения, например, рабочее напряжение светодиодный шарик 2,4 V в том случае, если его номинальное напряжение 3В;B. С неправильной полярностью: напряжение Отображает напряжение открытой цепи.4. Светодиодный тест-полоски: Установите напряжение около 200 в, измените ток, если требуется Регулировка яркости.

Метод тестирования без демонтажа экрана

Отключите питание от ТВ, отключите интерфейс розетки постоянного пластина тока и светильник бар, вставьте Красного и черного цветов ручки тестера в аноды и катоды интерфейса светодиодный светильник бар.1. Несколько светодиодный полоскиПроверка напряжения каждой ленты и запись их. Сравните Напряжение каждой ленты, это нормально, если разница <2 в или <3%.2. Однополосный светодиодныйА. Светодиодный индикатор не включен (для ремонта необходимо снять экран):Напряжение = 0, короткое замыкание. Напряжение ≥ 300 В, открытая цепь.B. Светодиодный индикатор горит (для определения нормальной подсветки или нет Нужны ссылки на тестирование платы драйвера постоянного тока).

Метод тестирования платы драйвера постоянного тока

Условия тестирования: Светодиодный индикатор подсветки включен с тестером, но он не работает с платой постоянного тока;А. Отключите питание от ТВ, отключите интерфейс розетки постоянного пластина тока и светильник бар;B. Подключите панель постоянного тока с тестером, используя кабели в наборе на правой полярности.C. Вставьте красные и черные ручки тестера в анод и катод интерфейса светодиодный светильникD. Включите питание телевизора.Е. Испытательное напряжение> 30 В, ток> 30 мА и стабильный, и светодиодный индикатор работает нормально, затем плата постоянного тока является нормальной.

Обратите внимание, что напряжение настраивается при открытии цепи, а ток регулируется во время короткого замыкания.

Введение дополнительной функции

Проверка напряжения электролитического конденсатора:Подключите черную ручку с катодом электролитического конденсатора и красной ручкой с анодом. Значение напряжения, отображаемое в вольтметре, будет быстро расти в начале. При достижении определенной точки скорость подъема заметно замедляется. В это время отображаемое значение напряжения-это фактическое Выдерживаемое Напряжение испытанного электролитического конденсатора. (Конденсаторы квалифицированы, если фактическое значение напряжения выше указанного значения напряжения)Примечание: Избегайте поломки конденсатора, время тестирования не должно быть слишком длинным.1. Установите напряжение около 20 в и ток до 1 мА при тестировании ссылки на напряжение диодов, триодов, MOS труб и IC.2. Установите напряжение около 330 в и ток до 1 мА при тестировании напряжения поломки конденсаторов, stabilivolts, пьезорезисторов и телевизоров.

Гарантия

1. Этот продукт гарантирован до одного года от покупки.2. Если есть некоторые проблемы с производительностью, просто верните его в исходное состояние в течение 30 дней с момента получения. В течение гарантийного срока, мы отремонтируем его и отправим вам хороший тестер.3. Гарантийный срок будет продлен на три месяца после ремонта.4. В течение гарантийного срока перевозка AA.5. Обратите внимание, что политика гарантии не распространяется на:А. Продукт поврежден человеком или случайно поврежден, например, чрезмерное входное напряжение, высокая температура, повреждение воды, падение иПоломки, механические повреждения и коррозии.B. Несанкционированная модификация и разрыв метка даты продукта.

|

KT4H-20200804-V4.2 |

||||||

|

||||||

|

||||||

|

|

|