昆山科瑞艾特电气有限公司

Add:江苏省昆山市古城路西侧新城翡翠湾 47 幢 505 室

PC: 215300

Tel:0512-50132715

Fax: 0512-50132716

联系人:周贵

手机:15862659855 13338649855

QQ:353850790 35731075 837638847 31740304

EMAIL:

网址:

昆山科瑞艾特电气有限公司是以自动化专业为主体集贸易、技术、工

程成套为一体的专业型公司。

一、经营品牌

1、欧陆 SSD 直流调速器 512C、514C、590C、590+及配件系列;

2、德国西门子全系列产品包括:

西门子 6RA28 系列直流调速器,西门子 6RA70 系列直流调速器;

zhougui8012@163.com

http://www.kunshan-create.com

S5-系列、S7-200 系列、S7-300 系列、S7-400 系列 CPU、功

能模块 FM、扩展模块 SM、接口模块 IM、通讯模块 CP 及相应附件、

配件、软件;

西门子工控机、人机界面 TD、OP、TP、MP、LOGO!、PS 电源、SITOP

电源、PROFIBUS 网络产品;

西门子各系列编程组态软件 STEP7-Micro/WIN、STEP7、WINcc、

PROTool;

西门子通用型变频器 MM420、MM430、MM440、6SE70 高性能变频

器、工程变频器

3、富 士:变频器、可编程控制器、伺服、数控系统、触摸屏 .

4、ABB:变频器、直流调速器.

5、AB(罗克韦尔)可编程控制器,变频器.

二、提供 SSD590 系列直流调速器维修服务,主要维修主板及电源板。

三、电控系统(电控成套及设备电控改造):

1、冶金行业:单(可逆)轧机、连轧机、酸洗线、拉弯矫直机、平

整机等;

2、线缆行业:成缆机、拉伸机、护套机、交联生产线;

3、橡塑行业:单/双螺杆挤出机、压延机、流延机、板/型材生产线

等.

4、机床控制系统的改造:龙门刨床,镗床,铣床等。

650 Series

AC Drive

Frame 1, 2 & 3

Product Manual

HA464828U003 Issue 7

Compatible with Version 4.9 Software onwards

WARRANTY

Parker SSD Drives warrants the goods against defects in design, materials and workmanship for the period of 12

months from the date of delivery on the terms detailed in Parker SSD Drives Standard Conditions of Sale IA058393C.

Parker SSD Drives reserves the right to change the content and product specification without notice.

© Copyright 2007 Parker SSD Drives, a division of Parker Hannifin Ltd.

All rights strictly reserved. No part of this document may be stored in a retrieval system, or transmitted in any

form or by any means to persons not employed by a Parker SSD Drives company without written permission

from Parker SSD Drives, a division of Parker Hannifin Ltd . Although every effort has been taken to ensure the

accuracy of this document it may be necessary, without notice, to make amendments or correct omissions.

Parker SSD Drives cannot accept responsibility for damage, injury, or expenses resulting therefrom.

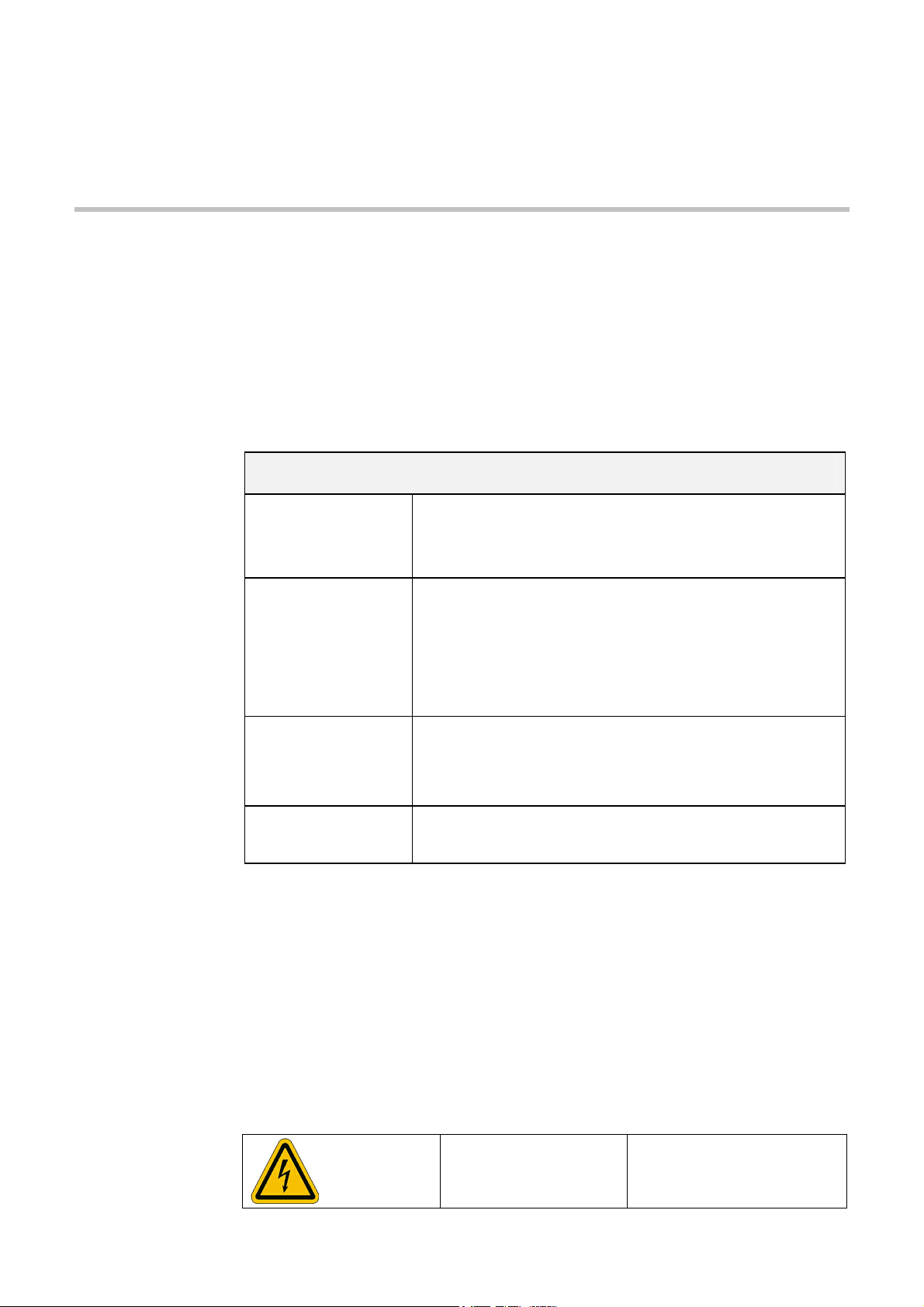

Requirements

IMPORTANT: Please read this information BEFORE installing the equipment.

Intended Users

This manual is to be made available to all persons who are required to install, configure or

service equipment described herein, or any other associated operation.

The information given is intended to highlight safety issues, EMC considerations, and to enable

the user to obtain maximum benefit from the equipment.

Complete the following table for future reference detailing how the unit is to be installed and

used.

INSTALLATION DETAILS

Serial Number

(see product label)

Where installed

(for your own

information)

Unit used as a:

(refer to Certification

for the Inverter)

Unit fitted:

R Component R Relevant Apparatus

R Wall-mounted R Enclosure

Application Area

The equipment described is intended for industrial motor speed control utilising AC induction or

AC synchronous machines.

Personnel

Installation, operation and maintenance of the equipment should be carried out by qualified

personnel. A qualified person is someone who is technically competent and familiar with all

safety information and established safety practices; with the installation process, operation and

maintenance of this equipment; and with all the hazards involved.

Product Warnings

Caution

Risk of electric

shock

Cont.2

Caution

Refer to

documentation

Earth/Ground

Protective

Conductor

Terminal

Hazards

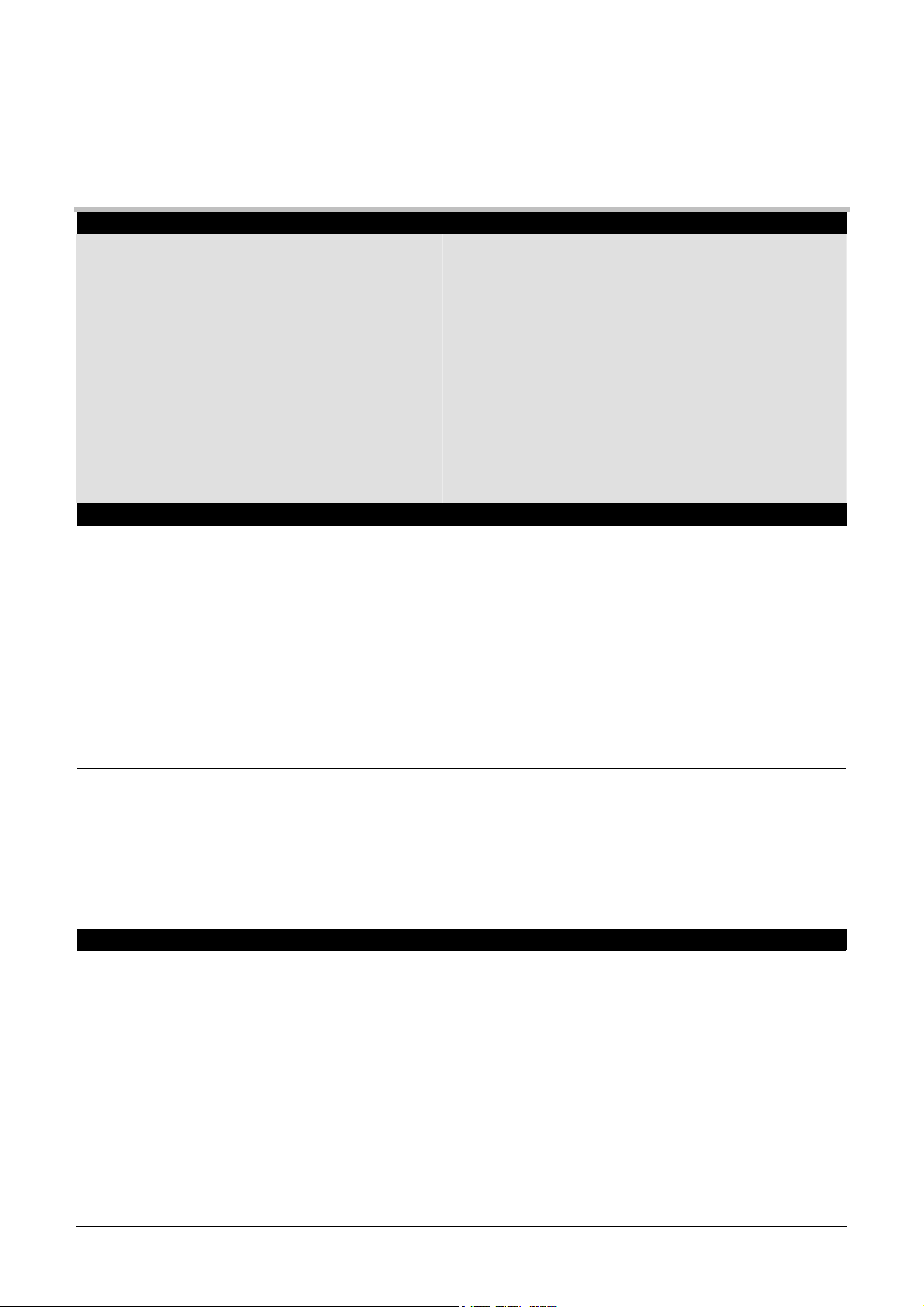

DANGER! — Ignoring the following may result in injury

1. This equipment can endanger life by exposure to

rotating machinery and high voltages.

2. The equipment must be permanently earthed due to

the high earth leakage current, and the drive motor

must be connected to an appropriate safety earth.

3. Ensure all incoming supplies are isolated before

working on the equipment. Be aware that there may

be more than one supply connection to the drive.

5. For measurements use only a meter to IEC 61010 (CAT

III or higher). Always begin using the highest range.

CAT I and CAT II meters must not be used on this

product.

6. Allow at least 5 minutes for the drive’s capacitors to

discharge to safe voltage levels (<50V). Use the

specified meter capable of measuring up to 1000V dc &

ac rms to confirm that less than 50V is present between

all power terminals and earth.

4. There may still be dangerous voltages present at

power terminals (motor output, supply input phases,

DC bus and the brake, where fitted) when the motor

is at standstill or is stopped.

7. Unless otherwise stated, this product must NOT be

dismantled. In the event of a fault the drive must be

returned. Refer to «Routine Maintenance and Repair».

WARNING! — Ignoring the following may result in injury or damage to equipment

SAFETY

Where there is conflict between EMC and Safety requirements, personnel safety shall always take precedence.

• Never perform high voltage resistance checks on the

wiring without first disconnecting the drive from the

circuit being tested.

• Whilst ensuring ventilation is sufficient, provide

guarding and /or additional safety systems to

prevent injury or damage to equipment.

• When replacing a drive in an application and before

returning to use, it is essential that all user defined

parameters for the product’s operation are correctly

installed.

• All control and signal terminals are SELV, i.e. protected

by double insulation. Ensure all external wiring is rated

for the highest system voltage.

• Thermal sensors contained within the motor must have

at least basic insulation.

• All exposed metalwork in the Inverter is protected by

basic insulation and bonded to a safety earth.

• RCDs are not recommended for use with this product

but, where their use is mandatory, only Type B RCDs

should be used.

EMC

• In a domestic environment this product may cause

radio interference in which case supplementary

mitigation measures may be required.

• This equipment contains electrostatic discharge

(ESD) sensitive parts. Observe static control

precautions when handling, installing and servicing

this product.

CAUTION!

• This is a product of the restricted sales distribution class

according to IEC 61800-3. It is designated as

“professional equipment” as defined in EN61000-3-2.

Permission of the supply authority shall be obtained

before connection to the low voltage supply.

APPLICATION RISK

• The specifications, processes and circuitry described herein are for guidance only and may need to be adapted to the

user’s specific application. We can not guarantee the suitability of the equipment described in this Manual for

individual applications.

RISK ASSESSMENT

Under fault conditions, power loss or unintended operating conditions, the drive may not operate as intended.

In particular:

• Stored energy might not discharge to safe levels

as quickly as suggested, and can still be present

even though the drive appears to be switched off

A drive is a component within a drive system that may influence its operation or effects under a fault condition.

Consideration must be given to:

• Stored energy • Supply disconnects • Sequencing logic • Unintended operation

• The motor’s direction of rotation might not be controlled

• The motor speed might not be controlled

• The motor might be energised

Cont.3

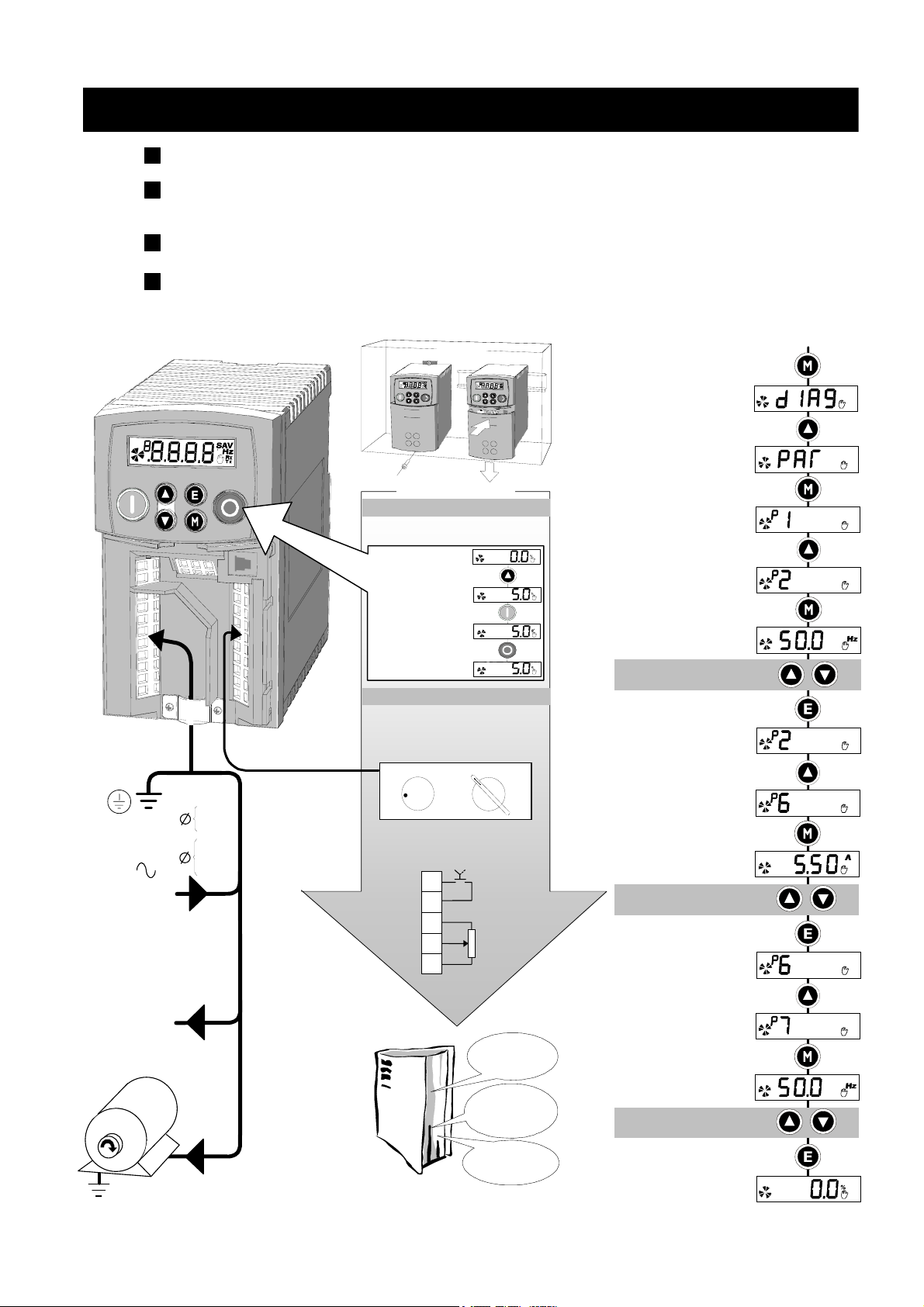

650 Quick Start

Mount the drive vertically in a lockable cubicle.

Is the drive to operate in Local (using the keypad) or Remote Control?

If Remote Control, make Control Connections.

Make Power Connections. Power-on and follow the Quick Set-Up procedure.

Apply a small setpoint. Start and stop the motor.

Frame 1

Mounting Options

Cubicle

Control Options

LOCAL CONTROL (DEFAULT)

Requires Power Connections only

Control is via the Keypad

Local Setpoint

Press to apply

a small setpoint

Press to start the

motor and it will ramp

to the setpoint

Press to stop the

motor and it will ramp

to zero

REMOTE CONTROL

Requires Power Connections and

Control Connections

Control is via your control panel

See Chapter 5 to select Remote

SPEED

STOP START

Quick Set-Up

Hold the M key until

DIAG is displayed

Navigate to the PAR menu

Press to enter the menu

and see the first parameter

Press to show the next

parameter

Press to edit the

MAX SPEED parameter

Adjust MAX SPEED

Press to exit the parameter

Press (4 times) to show P6

POWER-ON

Power

Supply

Motor

Thermistor

(link the terminals

if temperature

sensors not used)

Power Connections

1

3

L1

N

L1

L2

L3

TH1A

TH1B

M1/U

M2/V

M3/W

Match the motor

voltage to the

drive voltage

Refer to the

motor nameplate

for Star/Delta

voltages

0

100

Control Connections

Single Wire Starting

2-position switch

DIN1

+24V

+10V REF

AIN1

0V

7

6

4

2

1

Start

Speed

Reference

Chapters 3 and 4

install and run

the product

Chapter 5

details the

Keypad and

menu system

Chapter 9

holds many of the

technical details

PLEASE READ THE MANUAL

Press to edit the MOTOR

CURRENT parameter

Adjust MOTOR CURRENT

Refer to motor nameplate

Press to exit the parameter

Press to show P7

Press to edit the BASE

FREQUENCY parameter

Adjust BASE FREQUENCY

Press (3 times) to display

the Local Setpoint

Cont.4

Contents Page

Contents

Chapter 1 GETTING STARTED

Introduction ……………………………………………………………………………………..1-1

Equipment Inspection ………………………………………………………………………………….1-1

Storage and Packaging ……………………………………………………………………………….1-1

About this Manual …………………………………………………………………………….1-1

• Software Product Manual …………………………………………………………….1-1

Chapter 2 AN OVERVIEW OF THE D RIVE

Component Identification ………………………………………………………………….. 2-1

Chapter 3 INSTALLING THE DRIVE

Mechanical Installation …………………………………………………………………….. 3-1

Mounting the Drive……………………………………………………………………………………..3-1

Ventilation ………………………………………………………………………………………………..3-1

Electrical Installation ………………………………………………………………………… 3-2

Wiring Instructions………………………………………………………………………………………3-2

• Local Control Wiring ………………………………………………………………….. 3-2

• Remote Control Wiring……………………………………………………………….. 3-2

Connection Diagram………………………………………………………………………………….. 3-3

• Control Wiring Connections …………………………………………………………3-4

• Power Wiring Connections …………………………………………………………..3-4

• Terminal Block Acceptance Sizes…………………………………………………… 3-5

Optional Equipment ………………………………………………………………………….3-6

• Fitting the Remote 6511 Keypad …………………………………………………… 3-6

• Fitting the Remote 6521/6901/6911 Keypad………………………………….. 3-7

• RS485/RS232 Communication Module …………………………………………..3-8

• Line Choke…………………………………………………………………………….. 3-10

Chapter 4 OPERATING THE DRIVE

Pre-Operation Checks ……………………………………………………………………….4-1

Initial Start-up Routines …………………………………………………………………….4-1

Local Control Operation……………………………………………………………………………… 4-2

Remote Control Operation …………………………………………………………………………..4-2

Chapter 5 THE KEYPAD

Controlling the Drive using the Keypad………………………………………………. 5-1

Control Key Definitions………………………………………………………………………………..5-1

Display Indications ……………………………………………………………………………………..5-2

Drive Status Indications………………………………………………………………………………..5-2

The DIAGNOSTICS Menu ……………………………………………………………………5-2

The Menu System……………………………………………………………………………… 5-3

How To Change a Parameter Value ………………………………………………………………. 5-4

Special Menu Features ………………………………………………………………………5-4

Resetting to Factory Defaults (2-button reset)…………………………………………………….5-4

Changing the Drive Operating Frequency ……………………………………………………….5-4

Selecting Local or Remote Control…………………………………………………………………. 5-4

Password Protection ……………………………………………………………………………………5-5

Quick Application Selection ………………………………………………………………………….5-5

Selecting the Menu Detail ……………………………………………………………………………. 5-5

Chapter 6 PROGRAMMING YOUR A PPLICATION

MMI Parameters ………………………………………………………………………………. 6-1

• Configuring Terminal 10 (Digital Input/Output)………………………………..6-8

• PID — Tuning Your Drive ………………………………………………………………6-8

• Auto Restart……………………………………………………………………………… 6-9

• Skip Frequencies……………………………………………………………………… 6-10

Cont.5

Contents Page

Contents

• Minimum Speed Mode………………………………………………………………6-11

Product-Related Default Values ……………………………………………………………………6-11

• * Frequency Dependent Parameters ……………………………………………..6-11

• ** Power Dependent Parameters…………………………………………………. 6-12

Chapter 7 TRIPS AND FAULT FINDING

Trips ……………………………………………………………………………………………….. 7-1

Trip Warning Message ………………………………………………………………………………..7-1

What Happens when a Trip Occurs………………………………………………………………..7-1

Resetting a Trip Condition…………………………………………………………………………….7-1

Using the Keypad to Manage Trips…………………………………………………………………7-1

Hexadecimal Representation of Trips………………………………………………………………7-4

Fault Finding……………………………………………………………………………………. 7-5

Chapter 8 ROUTINE MAINTENANCE AND R EPAIR

Routine Maintenance………………………………………………………………………… 8-1

Repair ……………………………………………………………………………………………..8-1

Saving Your Application Data ……………………………………………………………………….8-1

Returning the Unit to Parker SSD Drives…………………………………………………………..8-1

Disposal ………………………………………………………………………………………………….. 8-1

Chapter 9 TECHNICAL SPECIFICATIONS

Understanding the Product Code …………………………………………………………………..9-1

• Model Number (Europe)………………………………………………………………9-1

• Catalog Number (North America)………………………………………………….9-2

Environmental Details………………………………………………………………………………….9-3

Power Details…………………………………………………………………………………………….9-3

User Relay ………………………………………………………………………………………………..9-3

Electrical Ratings ……………………………………………………………………………………….. 9-4

Analog Inputs/Outputs ………………………………………………………………………………..9-5

Digital Inputs …………………………………………………………………………………………….9-5

Digital Outputs ………………………………………………………………………………………….9-5

Cabling Requirements for EMC Compliance……………………………………………………. 9-5

Internal Dynamic Braking Circuit……………………………………………………………………9-6

External Brake Resistor ………………………………………………………………………………..9-6

Supply Harmonic Analysis (230V filtered) ……………………………………………………….9-7

Supply Harmonic Analysis (400V filtered) ……………………………………………………….9-8

Supply Harmonic Analysis (230V unfiltered)……………………………………………………. 9-9

Supply Harmonic Analysis (400V unfiltered)…………………………………………………..9-10

Chapter 10 C ERTIFICATION FOR THE DRIVE

Requirements for EMC Compliance ……………………………………………………10-1

Earthing Requirements……………………………………………………………………………….10-1

Requirements for UL Compliance ……………………………………………………… 10-1

European Directives and the CE Mark……………………………………………….. 10-3

CE Marking for Low Voltage Directive …………………………………………………………..10-3

CE Marking for EMC — Who is Responsible? …………………………………………………..10-3

EMC Compliance ……………………………………………………………………………..10-3

Certificates ……………………………………………………………………………………………..10-4

Chapter 11 S ERIAL COMMUNICATIONS

Connection to the P3 Port ………………………………………………………………… 11-1

Chapter 12 A PPLICATIONS

The Default Application ……………………………………………………………………12-1

How to Load an Application ……………………………………………………………..12-1

Application Description ……………………………………………………………………12-1

Cont.6

1GETTING STARTED

Introduction

The 650 Series AC Drive provides simple, compact, and low-cost speed control for 3-phase

induction motors.

It operates as an Open-loop Inverter (V/F Fluxing).

This manual describes the low-power end of the 650 product range for the following motor

power ratings:

Getting Started 1-1

Frame 1 230V 1 0.25 – 0.75kW 0.3 — 1.0 Hp

Frame 2 230V 1 1.1 – 1.5kW 1.5 — 2.0 Hp

Frame 2 400V 3 0.37 – 2.2kW 0.5 — 3.0 Hp

Frame 3 230V 1 2.2kW 3.0 Hp

Frame 3 230V 3 2.2 – 4.0kW 3.0 — 5.0 Hp

Frame 3 400V 3 3.0 – 7.5kW 4.0 — 10.0 Hp

The drive features:

• Local or Remote mode operation

• Support for RS485 and Modbus RTU comms protocols

• SELV control terminals (Safe Extra Low Volts)

• Intelligent monitoring strategy to avoid nuisance tripping

• In-built protection of the unit against overloads, excessive voltages, phase-to-phase and

phase-to-earth short circuits

• An internal RFI filter is fitted as standard

• An internal dynamic brake switch for connection to an external resistor (Frame 3: 230V, and

400V units only)

• Quiet operation

Note: Do not attempt to control motors whose rated current is less than 50% of the drive rated

current. Poor motor control or Autotune problems may occur if you do.

Nominal Input Voltage Phase Drive Power

Equipment Inspection

• Check for signs of transit damage

• Check the drive is suitable for your requirements by reading the Product Code on the rating

label. Refer to Chapter 9: “Technical Specifications” — Understanding the Product Code.

If the unit is damaged, refer to Chapter 8: “Routine Maintenance and Repair” for information on

returning damaged goods.

Storage and Packaging

Save the packaging in case of return. Improper packaging can result in transit damage.

If the unit is not being installed immediately, store the unit in a well-ventilated place away from

high temperatures, humidity, dust or metal particles.

About this Manual

This manual is intended for use by the installer, user and programmer of the drive. It assumes a

reasonable level of understanding in these three disciplines.

Note: Please read all Safety Information before proceeding with the installation and operation

of this unit.

It is important that you pass the manual on to any new user of this unit.

Software Product Manual

An accompanying Software Product Manual is available for download from the Parker SSD

Drives website: www.SSDdrives.com.

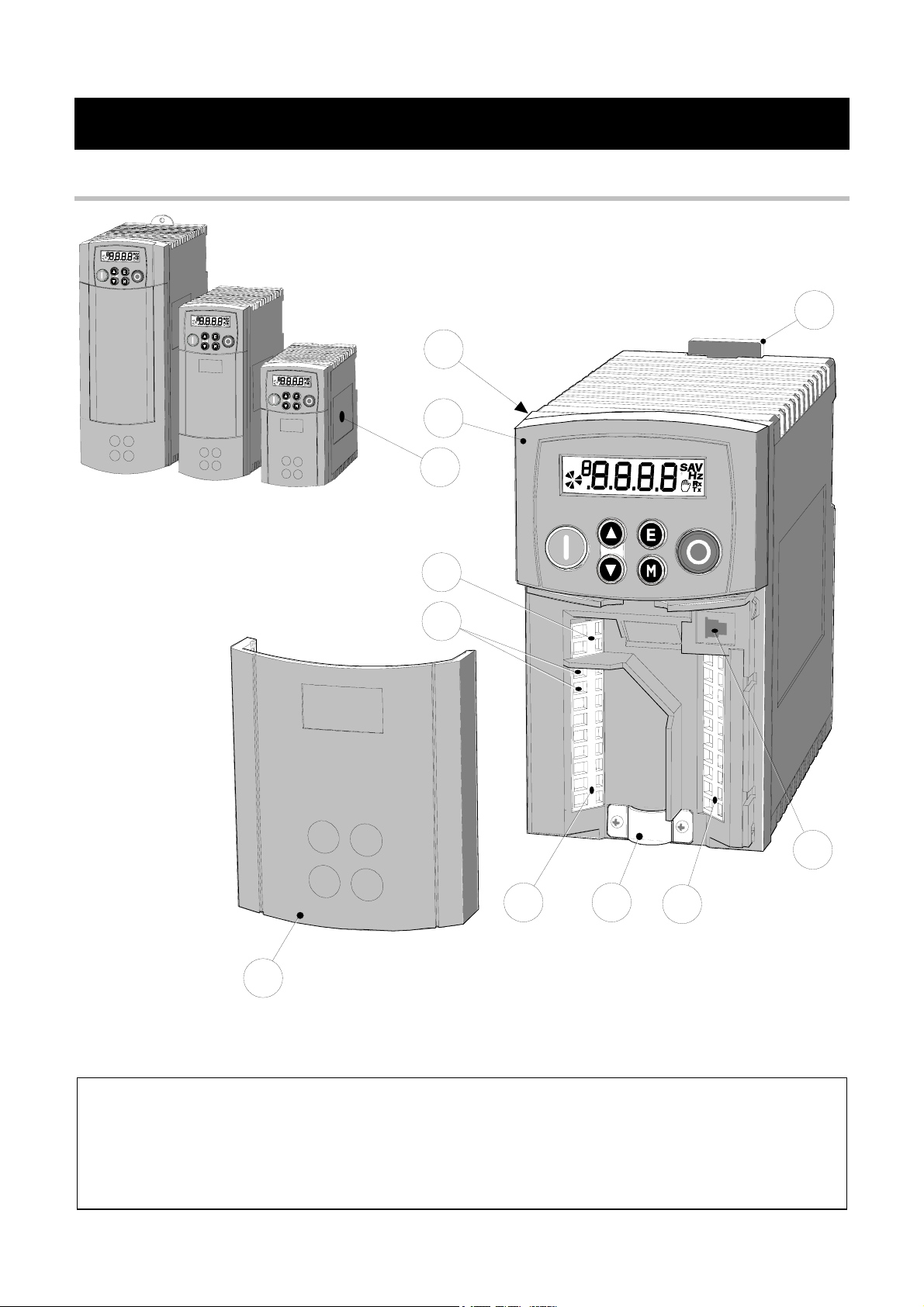

650 Series AC Drive

2-1 An Overview of the Drive

1AN OVERVIEW OF THE DRIVE

Component Identification

1

2

9

Frame 2 Frame 1Frame 3

3

8

10

5

4

Figure 2-1 View of Component Parts (Frame 1 illustrated)

6

11

7

1

Main drive assembly

2

Keypad

3

DIN clip/fixing bracket

4

Terminal cover

5

Power terminals

6

Motor cable screen clamp

7

Control terminals

8

Volt-free relay contacts

9

Product rating label

10

Motor thermistor terminals

11

RS232 port — P3 (optional)

650 Series AC Drive

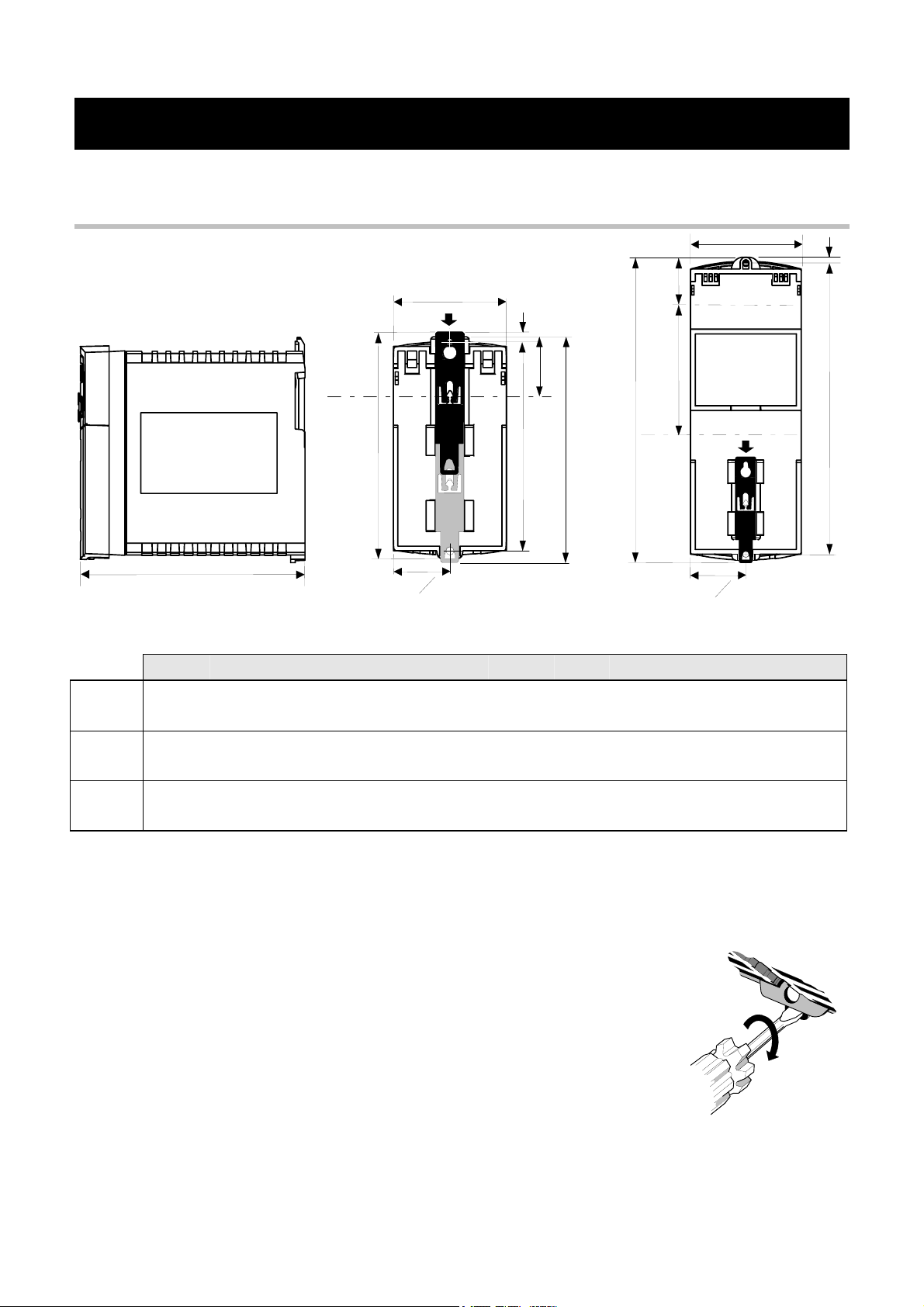

0INSTALLING THE DRIVE

IMPORTANT: Read Chapter 10: “Certification for the Drive” before installing this unit.

Mechanical Installation

Installing the Drive 3-1

D

SIDE VIEW — Frame 1 illustrated

The DIN clip is repositioned on Frames 1 and 2

to provide the upper fixing hole when wall-mounting

W

C

H1

H3

H4

DIN

centreline

H2

W

2

REAR VIEW — Frame 1 illustrated

(Frame 2 similar)

H2

W

H3

DIN

centreline

H4

DIN centreline

W

2

REAR VIEW — Frame 3

C

H1

Fixing Torque Weight H1 Fixing Centres H2 H3 H4 C W D

Frame 1 M4 1.5Nm 0.85kg 132 143 35 139 6 73 142

(5.2”) (5.6”) (1.4”) (5.5”) (0.2”) (2.9”) (5.6”)

Frame 2 M5 3.0Nm 1.4kg 188 201 35 194 6.5 73 173

(7.4”) (7.9”) (1.4”) (7.7”) (0.24”) (2.9”) (6.8”)

Frame 3 M5 3.0Nm 2.7kg 242 260 38 112 5 96 200

(9.5”) (10.2”) (1.5”) (4.4”) (0.2”) (3.8”) (7.9”)

Dimensions are in millimetres ( inches )

Mounting the Drive

Ventilation

650 Series AC Drive

To maintain compliance with European Electrical Safety Standard VDE0160(1994)/EN50178

(1998) the unit must be mounted inside a control cubicle that requires a tool for opening. The

cubicle should provide 15dB attenuation to radiated emissions between 30-100MHz.

Mount the drive vertically on a solid, flat, non-flammable, vertical

surface. It can be panel-mounted, or rail-mounted on a rail

complying with EN50022 (35mm DIN).

DIN Mounting

To DIN mount the unit, hang the unit on the top DIN rail and push

the unit onto the bottom DIN rail until it snaps in to position. Secure

with a lower screw fixing. To release the unit, use a flat bladed

screwdriver as shown.

Maintain a minimum air clearance for ventilation of 100mm (4 inches) above and below the

unit. When mounting two or more 650 units together, these clearances are additive. Ensure that

the mounting surface is normally cool. Be aware that adjacent equipment may generate heat and

also have clearance requirements. Provided the minimum clearance for ventilation is maintained,

650 drives may be mounted side-by-side.

lower

fixing

hole

3-2 Installing the Drive

Electrical Installation

IMPORTANT: Read the Safety Information on page Cont. 2 before proceeding.

Wiring Instructions

Local Control Wiring

This is the simplest installation. Every new drive will operate in

Local Control when first powered-up. The keypad is used to start

and stop the drive.

Refer to the Connection Diagram and install the:

• Thermistor cable, or link/jumper terminals TH1A and TH1B

if not used (we recommend you use a thermistor)

• Motor cable

• Supply cable

• Follow the earthing/grounding and screening advice

Refer to Chapter 4: «Operating the Drive»- Local Control

Operation.

Minimum Connections

To motor thermistor,

or link terminals

TH1A and TH1B

Remote Control Wiring

If operating in Remote Control you will use your control panel to start and stop the drive, via a

speed potentiometer and switches or push-buttons.

Your wiring of the control terminals will be governed by the Application you use: refer to

Chapter 12 for an explanation of the various Applications you can select and the appropriate

control wiring. Application 1 is the default Application.

The diagram below shows the minimum connections to operate the drive for single-wire

(switch) starting, and push-button starting. Other control connections for your Application,

shown in Chapter 12, and can be made to suit your system.

Referring to the Connection Diagram:

• Follow the instructions for Local Control Wiring, as detailed above

• Install using minimum connections (suitable for Application 1only), or refer to Chapter 12

and install the appropriate control wiring for your system

Minimum Connections for Application 1:

+10V REF

To motor thermistor,

or link terminals

TH1A and TH1B

Note: You can still operate the drive in Local mode, if necessary, with any Application selected.

Refer to Chapter 4: «Operating the Drive» and follow the relevant instructions for Single Wire

Starting or Push-Button Starting.

This product is designated as “professional equipment”

as defined in EN61000-3-2. Where enforced, permission of the supply authority shall

be obtained before connection to the low voltage domestic supply.

Ensure that all wiring is electrically isolated and cannot be made “live”

The drive is suitable for use with both earth referenced supplies (TN) and non-

earth referenced supplies (IT) when fitted with an internal ac supply EMC filter.

Single Wire Starting

DIN1

+24V

7

6

4

0V

2

1

unintentionally by other personnel.

AIN1

2-position

switch

Start

WARNING!

Speed

Reference

DIN4/DOUT2

DIN1

+24V

+10V REF

AIN1

0V

Push-Button Starting

10

Stop

Start

7

6

4

2

1

normally-closed

pushbutton

normally-open

pushbutton

Speed

Reference

650 Series AC Drive

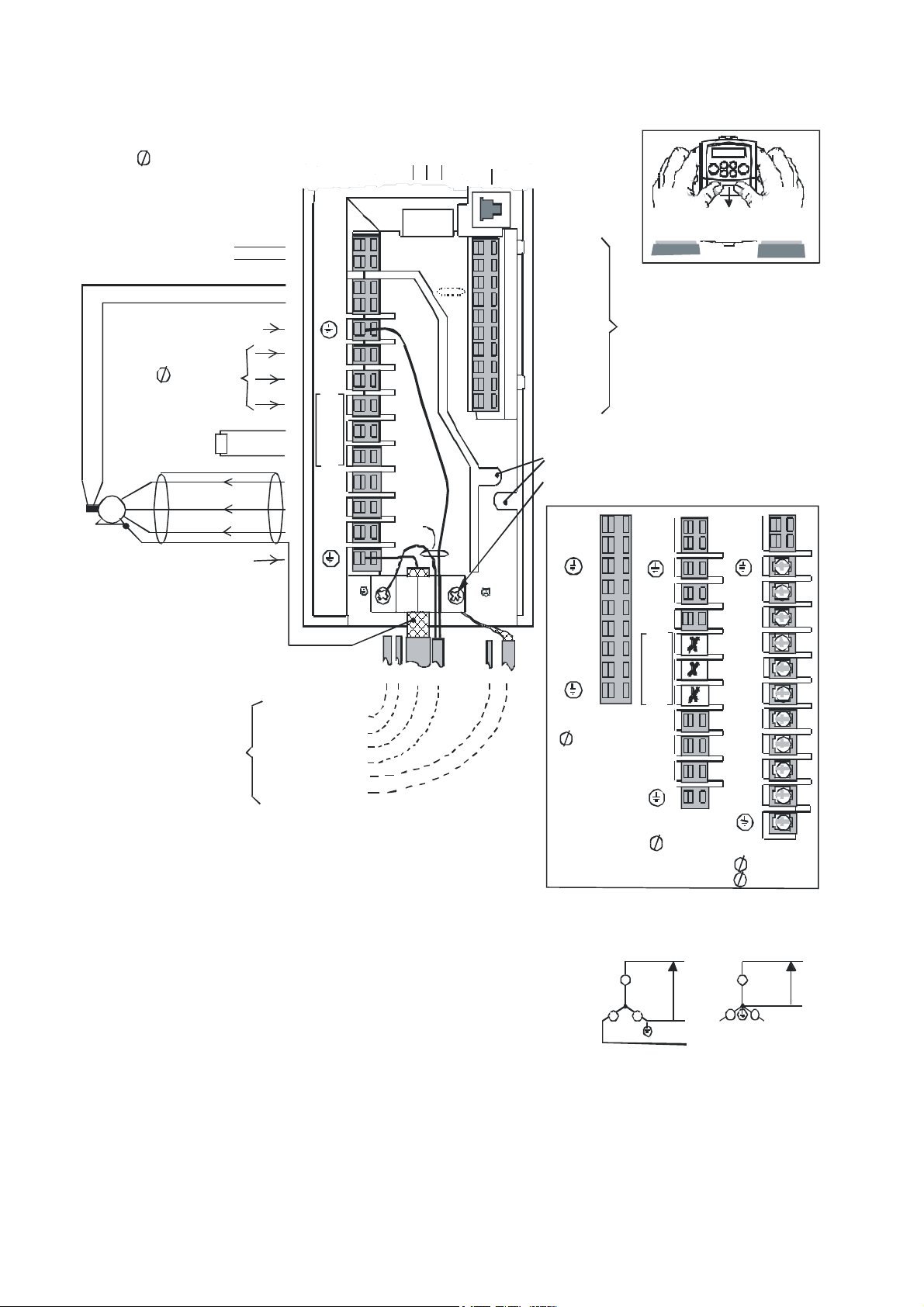

Connection Diagram

Frame 2

3 380-460V ac

(see Power Terminal Variations

inset for other frame sizes)

free

Volt Contacts

Motor Thermistor

Supply Prot ective Eart h/ Gr ound

380-46 0V ac

3

ext ernal b rake resis tor

(400V unit only)

M

Motor Protective Earth/Ground

screen

Installing the Drive 3-3

RS232

port

(fut ure op tio n)

13 12 11

fix cable

tie here

RL1A

RL1B

TH1A

TH1B

See Note 1

See

Note 2

L1

L2/N

L3

DC+

DBR

M1/U

M2/V

M3/W

use

two

separate

p rot ec t iv e

earth

wires

P3

To remove the Terminal Cover

press her e and slide down

10

DIN4/ DOUT 2

9

DIN3/ DOUT 1

8

DIN2

7

DIN1

6

+24V

5

AOUT1

4

+10V REF

3

AIN2

2

AIN1 *

1

0V

Wire Retain ers

Scre en Ear th/G roun d

TH1A

TH1B

Refer to Chapter 12: «Applications»

for specific cont rol wiring for each

Application

* If AIN1 is not used, connect to 0V

TH1A

TH1B

TH1A

TH1B

L1

1 : RL1 A, RL1B

Volt-free relay terminals can

be us ed a s ei t her `l iv e ’ or S ELV.

2 :TH1A, TH1B

Motor thermis tor connections are

regarded as a `live circuit’ and

mu s t no t be con n e ct e d to SELV ci rc uits .

Connect the 0V/COMMON t o protective earth/ground.

*

In a system comprisi ng more t han on e co ntrol ler,

connect the 0V/COMMON signals and join to

pr otec ti ve ear th/ gr oun d a t one poi nt onl y.

This is mandatory to meet the EMC spec ification stated.

Wiring Instructions

1 Remove the terminal cover from the drive.

2 Loose n the motor cable screen cla mp.

3 Connect the powe r supp ly cable, moto r cable and co ntro l c a bl es (if required ) .

4 Fast en the motor cable in place with the motor ca ble screen clamp.

Secure any control cable screen connections under the right hand screw.

Frames 2 & 3 only : Secure control cables under the wire retainers.

5 Connect t he the rmisto r an d u ser-rel ay i f re quired.

Frames 2 & 3 only: connect the dynamic brake if required (3 phase units only).

6 Us e a cable t ie an d secure al l the con trol cab le s and user — rel ay cables (i f fitte d)

as close to the control terminals as possible.

7 Co nnect the ancillary eq ui pment a s shown, for exampl e, an externa l br a ke resi stor.

8 Re-fit the terminal cover.

IMPORTANT:

Note that the 650 unit must be permanently earthed using two independent protective earth/ground incoming supply conductors.

screen and

connections

only

earth wire

shown for

clarit y

Motor Screen Earth/Ground

Dynamic Brake Cab le

Ther mi stor Cabl e

Motor Cable

Supply Cable

User Relay Cable

Cont rol C ables

L2/N

M1/U

M2/V

M3/W

Frame 1

1

220-240V ac

Power Terminal

Variations

Non-ea rth referenced

L1

L2/N

L3

DC+

DBR

M1/U

M2/V

M3/W

Frame 2

1 220-24 0V ac

IT

supply

The dri ve is s uitabl e for use with earth

refer enced supp lies (T N) and non -ea rth

refer enced supp lies (IT) when

fitted with an internal ac supply EMC filter.

L1

L2

L3

DC+

DBR

—

DC

M1/U

M2/V

M3/W

Frame 3

3 220-24 0V ac

3 380-46 0V ac

TN

Earth r eferenced

supply

650 Series AC Drive

3-4 Installing the Drive

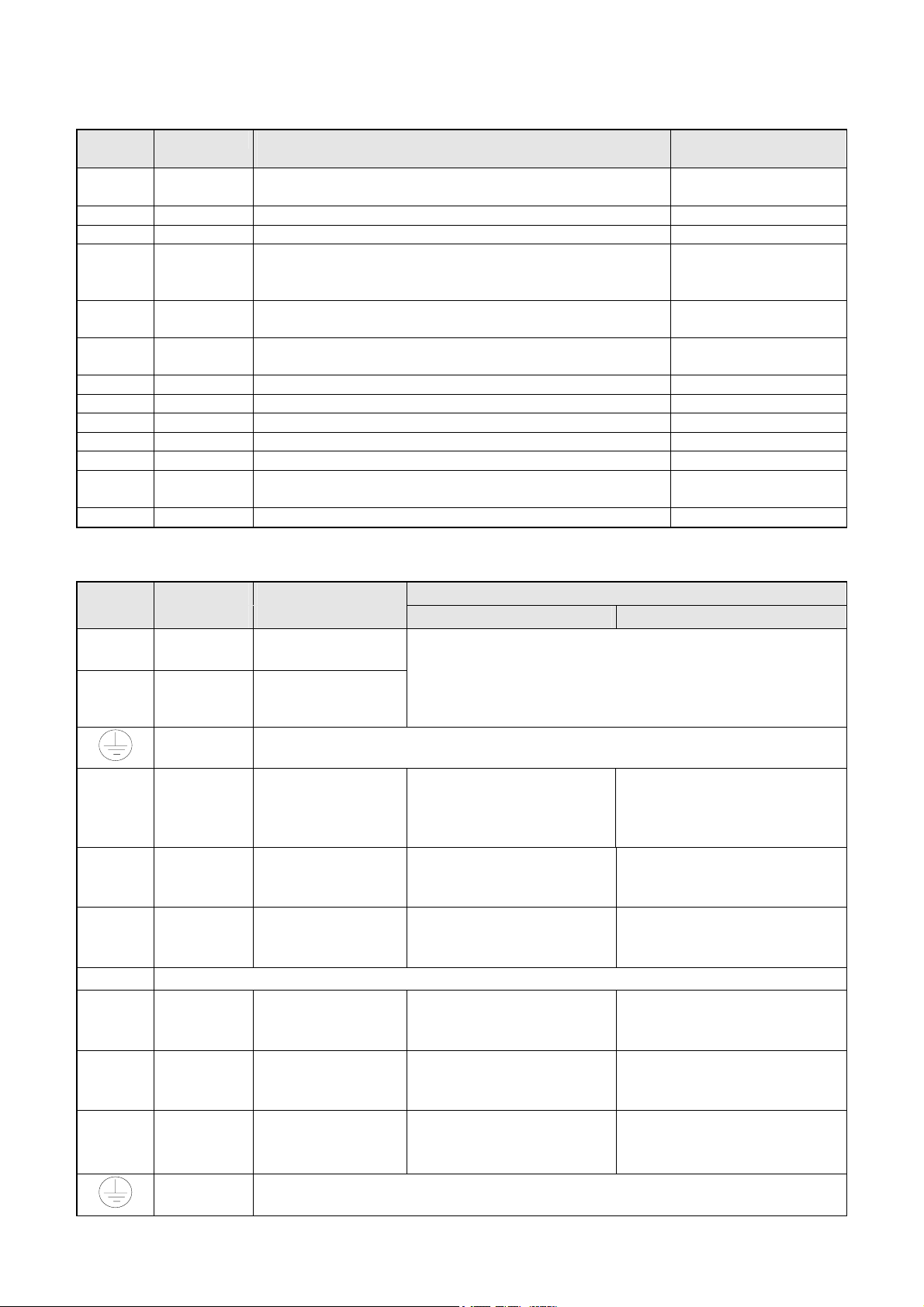

Control Wiring Connections

Terminal

(SELV)

P3 P3 RS232 port for use with remote-mounted RS232 keypad or

RL1A User Relay Volt-free contact 0-250Vac/24Vdc 4A

RL1B User Relay Volt-free contact 0-250Vac/24Vdc 4A

10 DIN4/

9 DIN3/

8 DIN2 Direction – configurable digital input:

7 DIN1 Run – configurable digital input: 0V = Stop, 24V = Run 0-24V

6 +24V 24V – 24V supply for digital I/O 50mA maximum

5 AOUT1 Ramp Output – configurable analog output (10mA loading) 0-10V

4 10VREF 10V — 10V reference (10mA maximum loading) 10V

3 AIN2 Feedback – analog input 2 0-10V, 4-20mA

2 AIN1 Setpoint – analog input 1.

1 0V 0V — 0V reference for analog/digital I/O 0V

Description Application 1 Default Function

(for other Applications refer to Chapter 12: “Applications”)

programming PC

Configurable digital input/output

DOUT2

DOUT1

Not Stop (input):

0V = No latching of Run (DIN1), 24V = Run latched

Jog – configurable digital input:

0V = Stop, 24V = Jog

0V = Forward, 24V = Reverse

If AIN 1 is not used, connect to 0V.

Power Wiring Connections

Range

—

0-24V source open

collector 50mA

maximum

0-24V

0-24V

0-10V

Terminal Description Function Range

200V 1-Phase 200V/400V 3-Phase

TH1A Thermistor Connection to motor

thermistor

TH1B Thermistor Connection to motor

thermistor

Reference

Terminal

L1 Power Input Single and three

L2/N

L2

L3 Power Input Three phase live

DC- No user connection

DC+ Dynamic

DBR Dynamic

M1/U

M2/V

M3/W

Power Input Single phase neutral

Brake

Brake

Motor

Outputs

Reference

Terminal

Supply protective earth (PE). This terminal must be connected to a protective (earth)

ground for permanent earthing.

phase live

connection

(or L2 three phase

live connection)

connection

Connection to

external brake

resistor

Connection to

external brake

resistor

Connection for

motor

Supply protective earth (PE). This terminal must be connected to a protective (earth)

ground for permanent earthing.

It is good practice to protect motors by fitting temperature

sensitive resistors. A typical resistance (up to a reference

temperature of 125°C) is 200Ω, rising rapidly to 2000Ω above

this temperature. Connect devices in series between TH1A and

TH1B. Link the terminals if temperature sensors are not used.

220/240V ac ±10% rms with

respect to L2/N. 50-60Hz

(IT/TN)

220/240V ac ±10% with

respect to L1. 50-60Hz

(IT/TN)

Not applicable 220/240V or 380/460V ac

Not applicable Frame 2 (high volt only) & 3.

Not applicable Frame 2 (high volt only) & 3.

Motor rated at:

0 to 220/240V ac

0 to 240Hz

220/240V or 380/460V ac

±10% rms with respect to L2, L3

phase-to-phase. 50-60Hz

(IT/TN)

220/240V or 380/460V ac

±10% with respect to L1, L3.

50-60Hz (IT/TN)

±10% with respect to L1, L2.

50-60Hz (IT/TN)

See “Internal Dynamic Brake

Switch” table

See “Internal Dynamic Brake

Switch” table

Motor rated at:

0 to 220/240V or 380/460V ac

0 to 240Hz

650 Series AC Drive

Installing the Drive 3-5

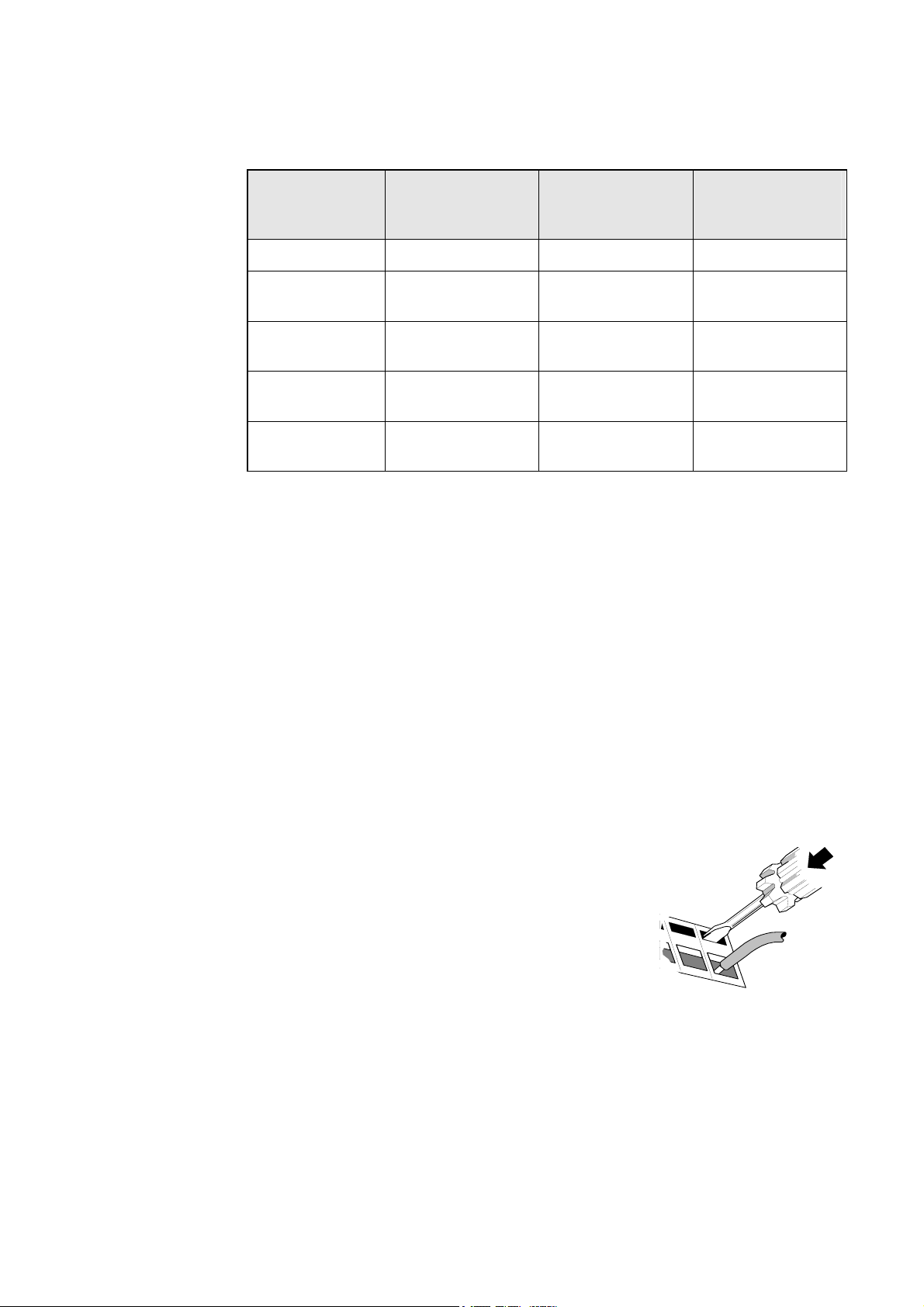

Terminal Block Acceptance Sizes

Wire sizes should be chosen with respect to the operating conditions and your local National

Electrical Safety Installation Requirements. Local wiring regulations always take precedence.

Frame Size Power Terminals

(maximum wire size)

Brake Terminals

(maximum wire size)

Thermistor/Control

Terminals

(maximum wire size)

Frame 1 2.5mm2/12 AWG Not Applicable 2.5mm2/12 AWG

Frame 2

200V

Frame 2

400V

Frame 3

230V

Frame 3

400V

2.5mm

2.5mm

6.0mm

6.0mm

2

/12 AWG Not Applicable 2.5mm2/12 AWG

2

/12 AWG 2.5mm2/12 AWG 2.5mm2/12 AWG

2

/10 AWG 6.0mm2/10 AWG 2.5mm2/12 AWG

2

/10 AWG 6.0mm2/10 AWG 2.5mm2/12 AWG

Power Wiring

Note: For specified EMC emission and immunity performance, install to EMC Installation

Instructions. Refer to Chapter 10: “Certification for the Drive” — for more information

Terminal tightening torque for Frame 3 power connections is 20 lb.in (2.26Nm).

Protect the incoming mains supply using the specified fuse, or RCD circuit breaker Type B.

IMPORTANT: We do not recommend the use of circuit breakers (e.g. RCD, ELCB, GFCI), however,

where their use is mandatory, they must:

• Operate correctly with dc and ac protective earth currents (i.e. type B RCDs as in

Amendment 2 of IEC755).

• Have adjustable trip amplitude and time characteristics to prevent nuisance tripping

on switch-on.

Control Wiring

Control wiring of between 0.08mm2 (28AWG) and 2.5mm2 (12AWG) can be used. Ensure all

wiring is rated for the highest system voltage. All control terminals are SELV (Safe Extra Low

Voltage), i.e. double-insulated from power circuits.

Using Cage Clamp Terminals

Strip the wire insulation to 5-6mm (0.20-0.24 inches), or

alternatively use wire-crimps. Insert a flat-bladed screwdriver,

maximum blade size 3.5mm. The cage provides the correct

force for a secure connection.

IMPORTANT: DO NOT lever or turn the screwdriver.

650 Series AC Drive

3-6 Installing the Drive

Optional Equipment

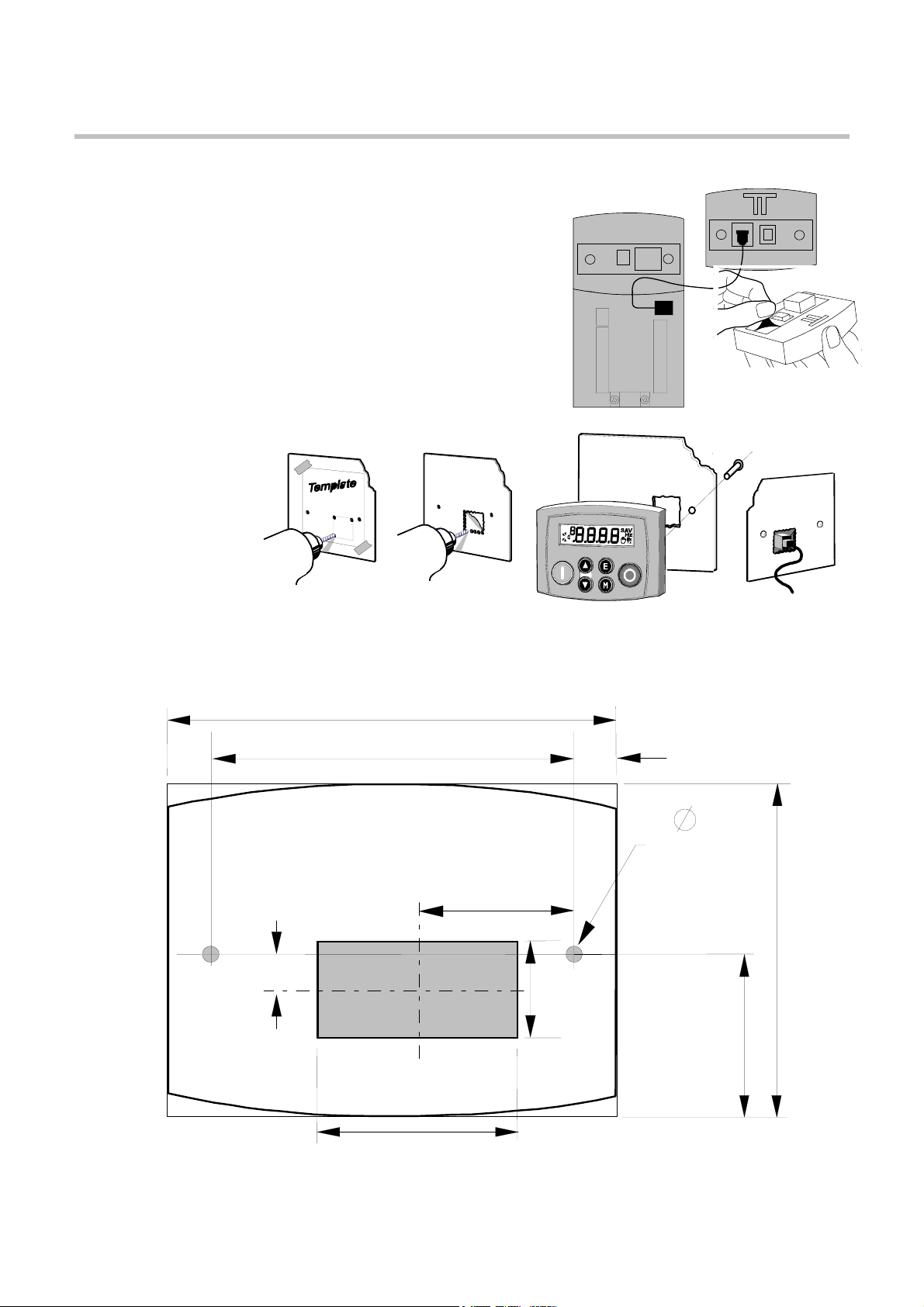

Fitting the Remote 6511 Keypad

You can remote-mount the drive-mounted Keypad using:

• the (optional) RS232 (P3) port located under

the terminal cover

• A standard P3 lead, Parker SSD Drives’ Part

Number CM057375U300, which is used to

connect the Keypad to the drive.

Two self-tapping screws are provided with the

Keypad. Remove the protective film from the

gasket. An enclosure rating of IP54 is achieved

for the remote Keypad when correctly mounted.

Assembly Procedure

1

P3

21

3

4

Cut-out Dimensions

The drawing below can be photocopied actual size (100%) and used as a template.

72mm

±

0.5

58

mm

Template

7mm

3.5

±

0.5

mm

15.5

±

mm

1

0

26mm

±

0.5

25

mm 5.5

Cut-out

±

0.5

0

P3

mm

54mm

32

2

±

mm

0

650 Series AC Drive

Installing the Drive 3-7

Fitting the Remote 6521/6901/6911 Keypad

The 6052 Mounting Kit is required to remote-mount a 6521 Keypad. An enclosure rating of

IP54 is achieved for the remote Keypad when correctly mounted using the 6052 Mounting Kit.

6052 Mounting Kit Parts for the Remote Keypad

Tools Required

No. 2 Posidrive

screwdriver.

Assembly Procedure

Cutout Dimensions

An actual size template is provided with

the Keypad/6052 Mounting Kit.

Figure 3-1 Mounting Dimensions for

the Remote-Mounted Keypad

6521/6901/6911

650 Series AC Drive

6901

The 6901/6911 keypad,

supplied with 690+

products, may be

remote mounted and

connected to the 650V

drive in the same way.

3-8 Installing the Drive

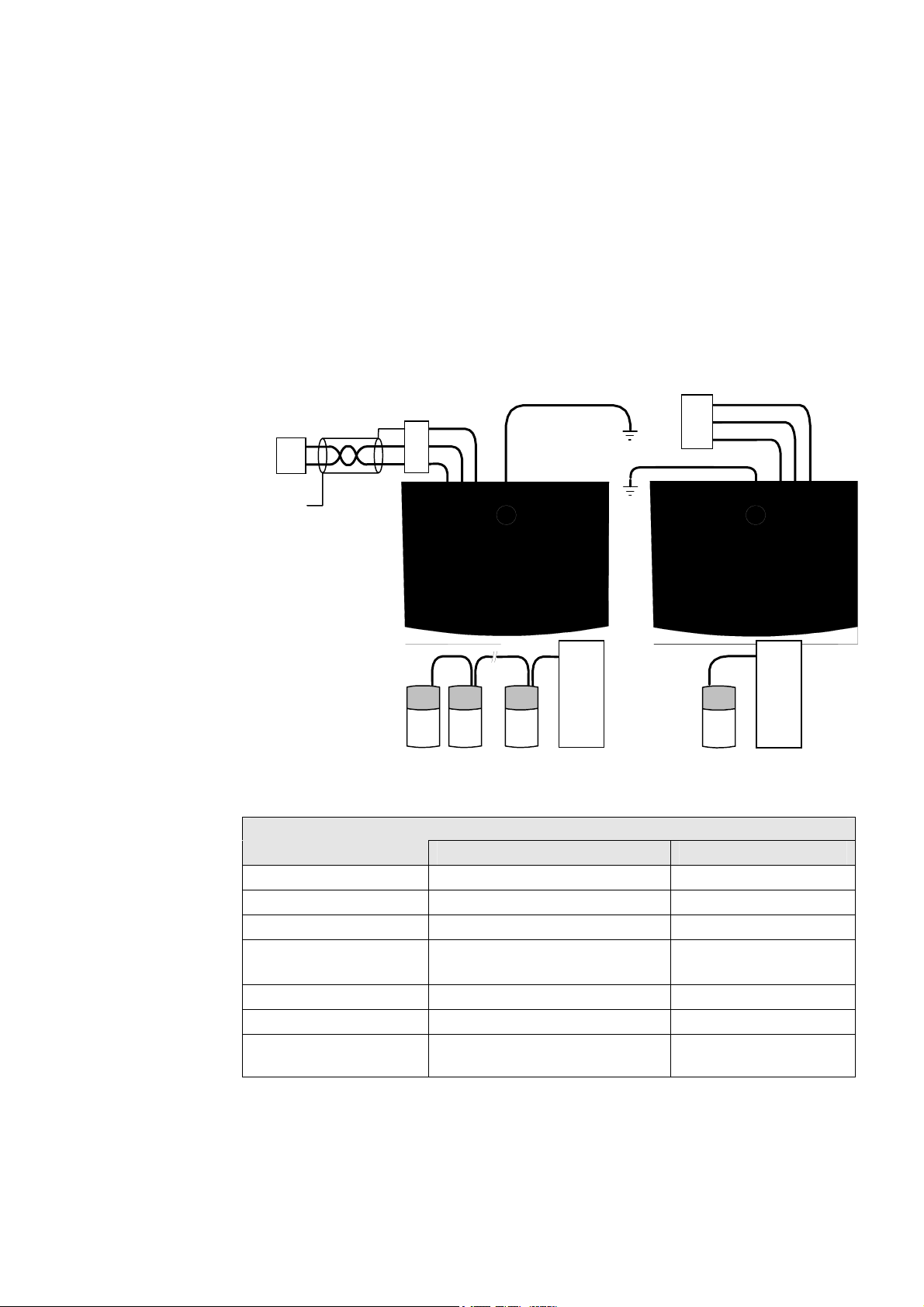

RS485/RS232 Communication Module

You can create a network of drives by linking a Master (PC/PLC) to one or more 650 drives

fitted with this module.

Plug this Communication Module on to the front of the 650 drive, replacing the keypad.

It converts signals from the host 650 drive into RS485 or RS232, and vice versa, so that

information can be shared between the Master and 650 drive(s).

Wiring is very simple — all connections are SELV (Safe Extra Low Voltage). Select to use

RS485 or RS232 by wiring to the appropriate terminal on the module.

Note: RS485 and RS232 terminals cannot be used simultaneously.

We recommend you ground the module to the system earth using the Functional Earth terminal.

PC/PLC

9-Way / 25-Way

D-Type

Connector

B

A

To PC/PLC

Chassis

650 Drive

with

Module

Scn

B

A

Functional

Earth

PC/PLC

9-Way or 25-Way

D-Type Connector

0V

Tx

Rx

PC/PLC

Master

Drive Drive Drive

master to single/multiple slave

RS485 Connections

PC/PLC

Master

Drive

master to single slave only

RS232 Connections

Wiring Specifications

RS485 Connections RS232 Connections

Network Type

Connections

Signal Levels

Receiver Input

Impedance

Maximum Cable Length

Maximum Baud Rate

Maximum Number of

Units

2-Wire Shielded Twisted-Pair 3-Wire Un-Shielded Cable

A=RxA/TxA, B=RxB/TxB, Shield Rx, Tx, Ground (0V)

To RS485 Standard To RS232 Standard

¼ Unit Load

3 kΩ minimum

7kΩ maximum

1200m (4000ft) 3 metres

57.6kbaud 57.6kbaud

32 including slaves and masters

2: 1 master and 1 slave

only

650 Series AC Drive

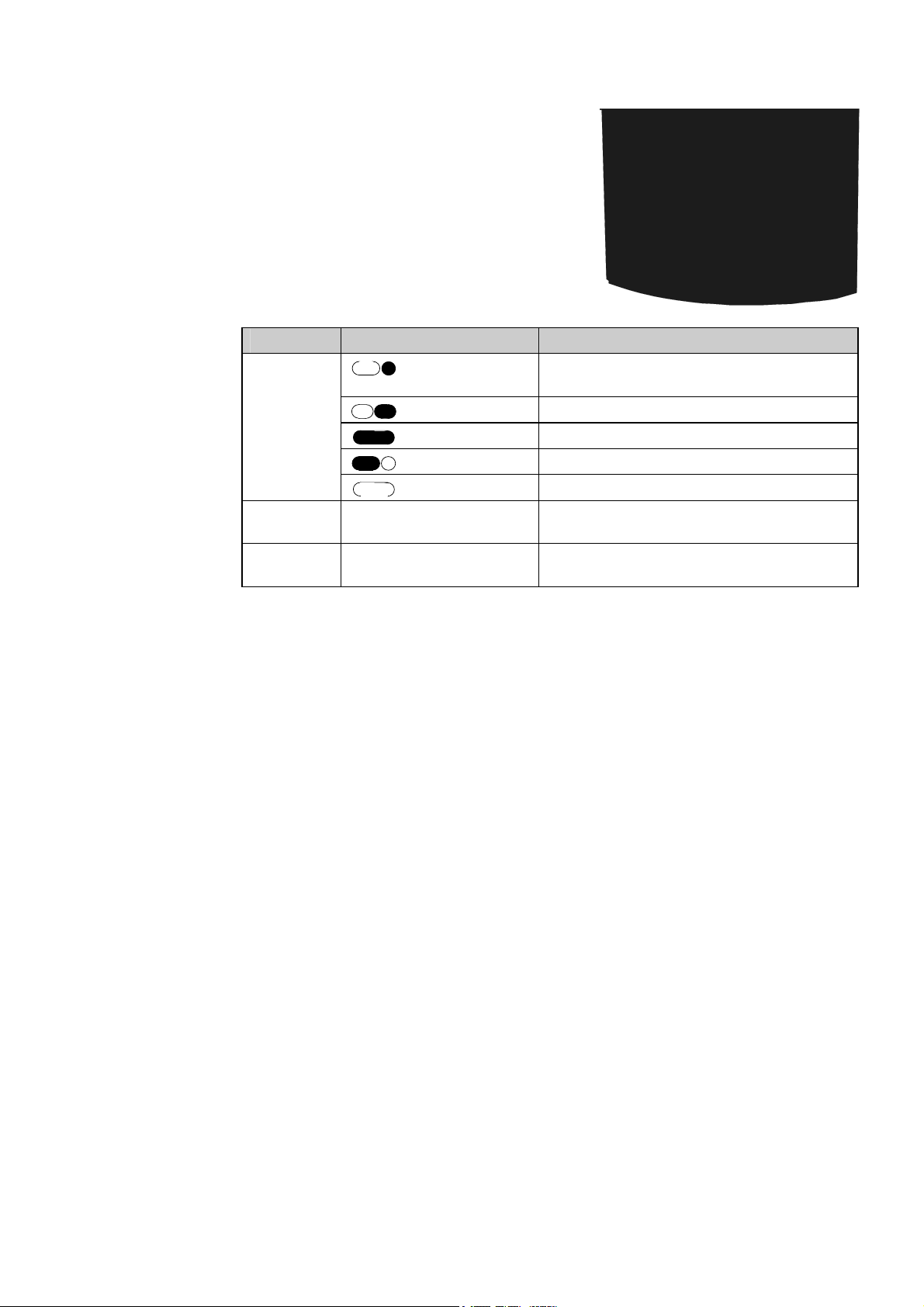

LED Indications

The module has three LEDs providing diagnostic

information about the 650 host drive’s ‘Health’,

‘Receive’ and ‘Transmit’ activity.

HEALTH = Green, Rx = Red, Tx =Red

LED Name LED Duty Drive State

HEALTH

Rx

Tx

SHORT FLASH

EQUAL FLASH

ON

LONG FLASH

OFF

INTERMITTENT

INTERMITTENT

Re-configuration, or corrupted non-volatile

memory at power-up

Tripped

Healthy

Braking

No drive power, or serious hardware fault

Indicates activity on the ‘receive’ line carrying

data from the Master

Indicates activity on the ‘transmit’ line carrying

data to the Master

Installing the Drive 3-9

Configure the Drive

Before the module can be used you must configure the drive to your system. Set-up the

parameters in the SERIAL menu as appropriate. Refer to Chapter 6: «Programming Your

Application» — SET::SERL Menu, parameters

For Tag number information refer to the 650 Software Product Manual, available on the Parker

SSD Drives website: www.SSDdrives.com.

Note: This Option can only be used on drives using software version 4.1 or higher.

S

SE01 to SSE08.

650 Series AC Drive

3-10 Installing the Drive

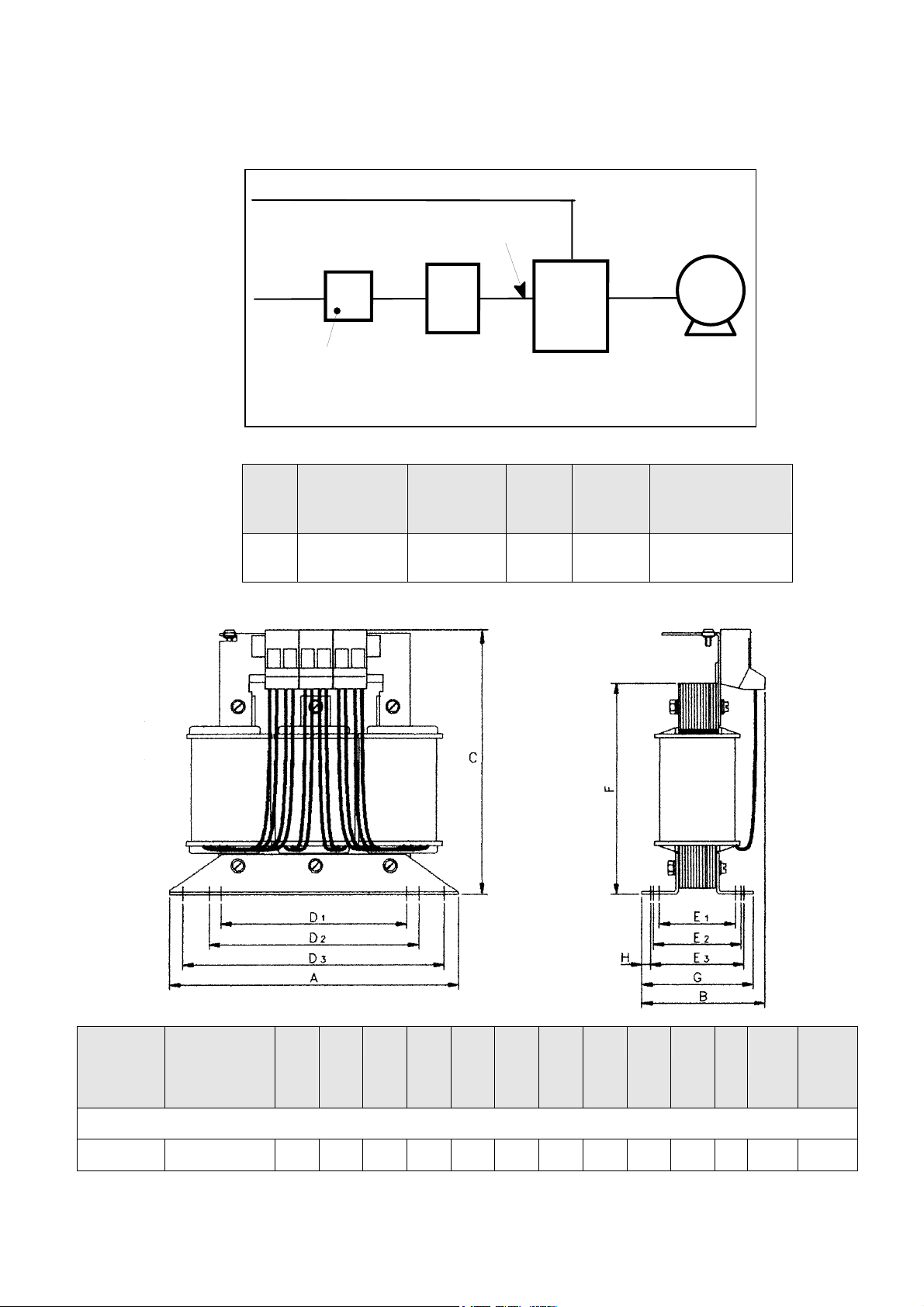

Line Choke

Cables are considered to be electrically sensitive, clean or noisy. A line choke is used to reduce

harmonic emission to meet the limits of EN61000-3-2.

signal/control cable

(sensitive)

power

supply

cable

(clean)

fuse or suitable

circuit breaker

(RCD not

recommended)

The choke is for use on the following drive:

line

choke

(noisy)

drive

motor

cable

(noisy)

motor

Phase Drive Nominal

Input Voltage

(V)

3 400 0.37/0.5 6 4.88

Drive Power

(kW/hp)

Rated

Current

(Aeff)

Rated

Inductivity

(mH)

Choke

Part Number

CO467763U003

(Europe)

Rated

Current

(Aeff)

6 4.88 148 76 151 90 100 136 39 45 49 110 69 M4 2.1/

Rated

Inductivity

(mH)

* dimension is dependent of the air gap

A

B C D1 D2 D3 E1 E2 E3 F* G Fixing

(mm)

650 Frame 2, 3-phase, 400V, 0.37kW/0.5Hp

Weight

Screws

(kg/lbs)

650 Series AC Drive

Operating the Drive 4-1

1OPERATING THE DRIVE

Pre-Operation Checks

WARNING!

Wait for 5 minutes after disconnecting power before working on any part of the system or removing the

terminal cover from the drive.

Initial checks before applying power:

• Check for damage to equipment.

• Mains power supply voltage is correct.

• Motor is of correct voltage rating and is connected in either star or delta, as appropriate.

• Check all external wiring circuits — power, control, motor and earth connections.

Note: Completely disconnect the drive before point to point checking with a buzzer, or when checking

insulation with a Meggar.

• Check for loose ends, clippings, drilling swarf etc. lodged in the drive and system.

• If possible check that the motor can be turned freely, and that any cooling fans are intact and free from obstruction.

Ensure the safety of the complete system before the drive is energised:

• Ensure that rotation of the motor in either direction will not cause damage.

• Ensure that nobody else is working on another part of the system which will be affected by powering up.

• Ensure that other equipment will not be adversely affected by powering up.

Prepare to energise the drive and system as follows:

• Remove the supply fuses, or isolate using the supply circuit breaker.

• Disconnect the load from the motor shaft, if possible.

• If any of the drives control terminals are not being used, check whether these unused terminals need to be tied high

or low.

• If the motor thermistor terminals are not connected to a motor thermistor, connect these terminals together.

• Check external run contacts are open. Check external speed setpoints are all zero.

Re-apply power to the drive and system

Initial Start-up Routines

Note: Refer to Chapter 5: “Using the Keypad” to familiarise yourself with the keypad’s

indications, and how to use the keys and menu structure.

!

!

IMPORTANT

When power

is applied to

IMPORTANT

the drive in

On power-up

Remote

in Remote

Control, it will

Control, the

immediately

drive will

start running if

immediately

the RUN

start running if

signal is

the RUN

active.

nal is

si

Note: If during the start-up routine the display shows either an alarm

The drive can be started in either Remote Control or Local Control. By default, the drive will

start in Local Control.

These routines assume that the drive’s control terminals are wired as shown in the Control

Wiring Connections in Chapter 3.

Connected in this way, a positive setpoint will rotate the motor in a clockwise direction when

viewed down the shaft, looking toward the motor.

(indicated by the letter “A”) or a flashing Warning message,

refer to Chapter 7: “Trips and Fault Finding”.

Unpredictable motion, especially if motor parameters are incorrect.

Ensure no personnel are in the vicinity of the motor or any connected machinery.

Ensure that machinery connected to the motor will not be damaged by

Ensure that the emergency stop circuits function correctly before running the motor

WARNING!

unpredictable motion.

for the first time.

A typical alarm

650 Series AC Drive

4-2 Operating the Drive

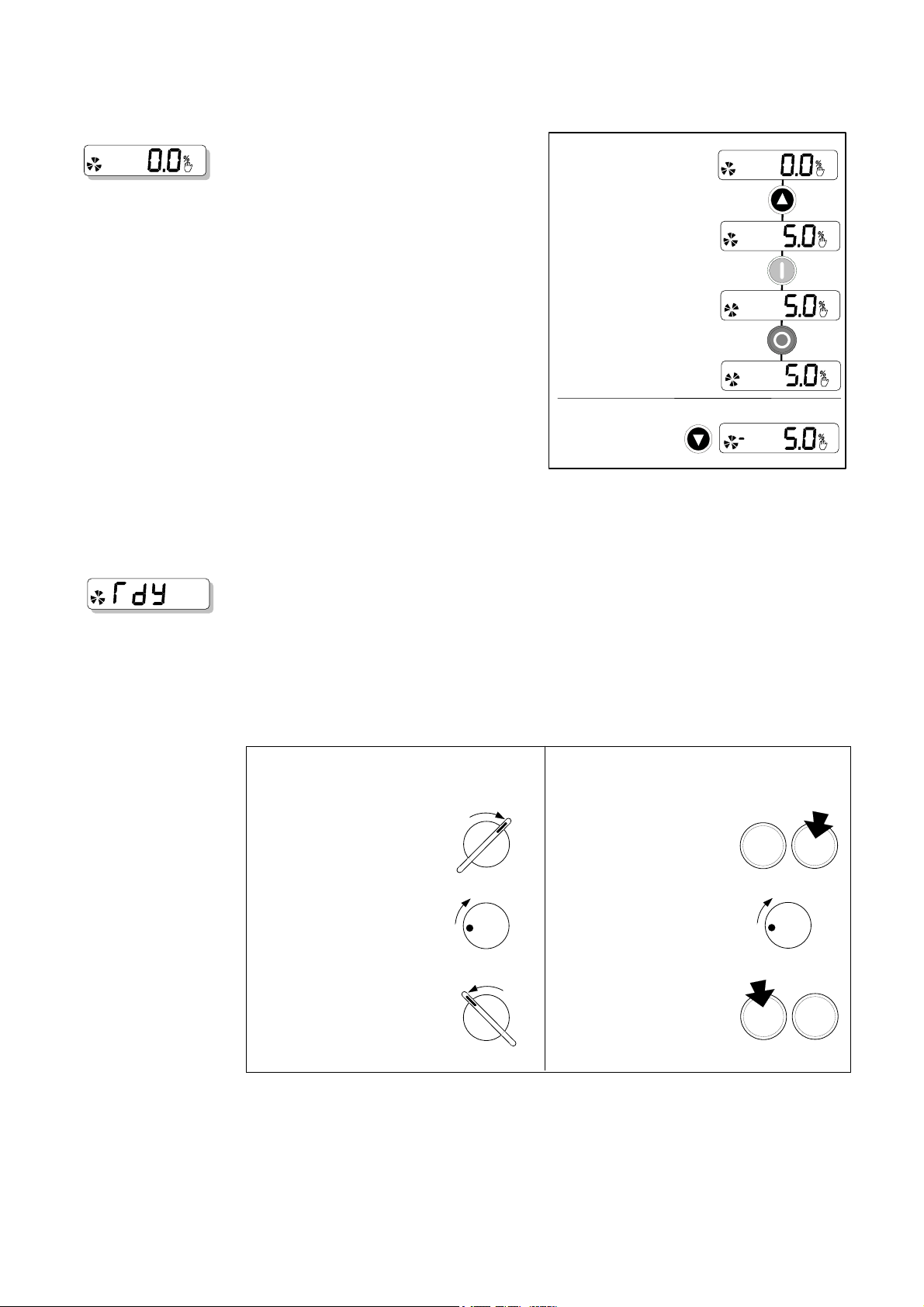

Local Control Operation

LOCAL

This is the simplest method of operating the

drive. Connect the keypad to the drive and

power -up the unit.

The drive will display the Local screen. If not,

refer to Chapter 5 and select Local Control.

Follow the instructions opposite to start and

stop the motor.

Reverse: Instead of setting a negative

setpoint, you can reverse the motor direction

by pressing STOP + T, or START + T.

To change the direction to forwards, (the

normal direction), press STOP + S or

START + S.

LOCAL

Press to apply a small setpoint

(see Reverse below)

Press to start the motor

and it will ramp to the setpoint

Press to stop the motor

and it will ramp to zero

Note that the Setpoint parameter will not

change sign to indicate this change, however

the rotating indicator on the MMI will show

the direction.

Reverse

From zero, release

and press again for

a negative setpoint

We recommend that you use the STOP key commands if the motor is stopped, and the START

key commands if the motor is running. The keys should be pressed and released together.

Remote Control Operation

REMOTE

IMPORTANT: Ensure that the speed potentiometer is set to zero.

Connect the keypad to the drive and power-up the unit.

The drive will display the Local screen. Refer to Chapter 5 and select Remote Control.

Follow the instructions below to start and stop the motor using your control panel.

Reverse the motor’s direction of rotation using the DIN2 connection (0V = forward, +24V =

reverse). Alternatively, swap two of the motor phases (WARNING: Disconnect the mains

supply first).

Single Wire Starting Push-button Starting

STOP START

Close the RUN switch (DIN1)

Apply a small speed setpoint

and the motor will ramp to

the setpoint

Open the RUN switch (DIN1)

and the motor will ramp to zero

RUN SWITCH

5

0

POTENTIOMETER

STOP START

RUN SWITCH

Press the Start button

(DIN1)

Apply a small speed setpoint

and the motor will ramp to

100

the setpoint

Press the Stop button

(DIN4/DOUT2)

and the motor will ramp

to zero

(Applications 1 & 5 only)

STOP

PUSHBUTTONS

0

POTENTIOMETER

STOP

PUSHBUTTONS

START

5

100

START

The installation of your drive is now complete:

The drive will operate as an open-loop drive. It is programmed to control an induction motor of

equivalent power, current, and voltage rating to the drive.

The drive’s default parameters will operate effectively under most circumstances, however you

may wish to refer to Chapter 6 to tune the drive to your system.

650 Series AC Drive

Loading…

Серия универсальных преобразователей AC650/AC650V предназначена для использования в различных областях промышленности: вентиляционные системы, подъемные механизмы, химическая промышленность, автопромышленность, деревообработка, производство стройматериалов, обработка металла.

Отличительные особенности:

- ЖК-дисплей с подсветкой

- ПИД — регулирование

- Встроенный ЭМС-фильтр

- Защищенная паролем клавиатура

- Встроенный тормозной резизстор

- Степень защиты IP20

- Модуль клонирования 6514/00

- TTL-панель управления 6511/TTL/00

- Запрограммированные макросы приложений: насосы, вентиляторы, компрессоры, конвейеры, станки

- Векторный тип управления

Дополнительная информация:

Переход в раздел технической документации

Запросить дополнительную информацию и цены

Parker 650 Series Controller PDF User Guides and Manuals for Free Download: Found (3) Manuals for Parker 650 Series Device Model (Product Manual, Safety Booklet & Quickstart, Easy Start Manual)

The Parker 650 Series is a notable offering from one of the leading manufacturers in the industry. Known for its reliability and innovative features, this series has captured the attention of professionals across various sectors. The product line is designed to meet the high standards of engineering performance, making it an attractive option for those seeking precision and durability.

One of the standout aspects of the Parker 650 Series is its versatility. Engineers and project managers appreciate the adaptability of this product in different applications. Whether you’re working in industrial settings, automotive environments, or any other technical domain, the 650 Series provides solutions that can be tailored to meet specific needs. This adaptability is complemented by its robust construction, ensuring that it can withstand the rigors of daily use.

The design of the Parker 650 Series is both functional and ergonomic. The intuitive layout allows for straightforward operations, which is essential in high-pressure environments where time is of the essence. This user-friendly aspect doesn’t compromise its technical capabilities. The series is packed with advanced features that enhance its overall performance. These include:

- Highly efficient functionality that reduces downtime.

- Innovative control systems that improve precision in handling.

- Durable materials that resist wear and tear.

Another significant benefit of the Parker 650 Series is its energy efficiency. In today’s world, where sustainability is paramount, this series stands out by providing products that not only perform well but also minimize energy consumption. This feature does not only contribute to lower operational costs; it also aligns with broader environmental goals, making it a responsible choice for businesses.

Customer feedback on the Parker 650 Series has been largely positive, reflecting high satisfaction rates among users. Many commend its reliability, stating that it consistently delivers results without frequent maintenance. This reduces operational interruptions, allowing teams to focus on their core responsibilities.

Moreover, the technical support provided by Parker is exceptional. With a dedicated team ready to assist clients in troubleshooting and optimizing their use of the 650 Series products, the overall experience is enhanced significantly. This level of customer service fosters trust and loyalty, which are vital in today’s competitive market.

In summary, the Parker 650 Series represents a perfect blend of innovation, efficiency, and reliability. For professionals seeking top-tier equipment that can elevate their projects, this series provides a compelling solution. Its adaptability across multiple applications, combined with exceptional customer support, makes it a wise investment for any organization focused on quality and performance.

Скачать

Compumotor

OEM650/OEM650X

OEM350/OEM350X

Drive and Drive/Indexer

User Guide

Compumotor Division

Parker Hannifin Corporation

p/n 88-013157-02 A

RE

MO

TE

RE

F

CU

RR

EN

T

DU

MP

VD

C+

VD

C-

A+

A-

B+

B-

Co

mp

um

oto

r

OEM

OEM

s

e

r

i

e

s

DRI

V

E

D

R

IV

E

DRIVE

D

R

IV

E

POWER

FAULT

На этой странице вы можете совершенно бесплатно скачать Инструкция по эксплуатации Parker Products OEM650.

У документа PDF Инструкция по эксплуатации 58 страниц, а его размер составляет 373 Kb.

Читать онлайн Сетевые карты Parker Products OEM650 Инструкция по эксплуатации

Google Ads:

Скачать файл PDF «Parker Products OEM650 Инструкция по эксплуатации» (373 Kb)

Популярность:

5171 просмотры

Подсчет страниц:

58 страницы

Тип файла:

Размер файла:

373 Kb

Google Ads:

Google Ads: